When It Has to Be Right.

Aluminum Alloy Extrusion Process

One-Stop Solution for Precision Irregular Profile Forming

From heavy billets to intricate cross-sections, two decades of accumulated technology ensure every complex shape is precisely formed.

Choosing the Right Metal Enclosure Fabrication Process

To select the optimal process for a metal enclosure, we prioritize matching the design requirements with manufacturing capabilities based on volume, complexity, and cost structure.

Seamless Sections & Low Tooling

We leverage Aluminum Extrusion when the design requires a consistent profile (often used for heat sinks, rail systems, or simple enclosures) to benefit from Near-Net-Shape forming and rapid setup.

For Maximum Cost-Efficiency in High Volume

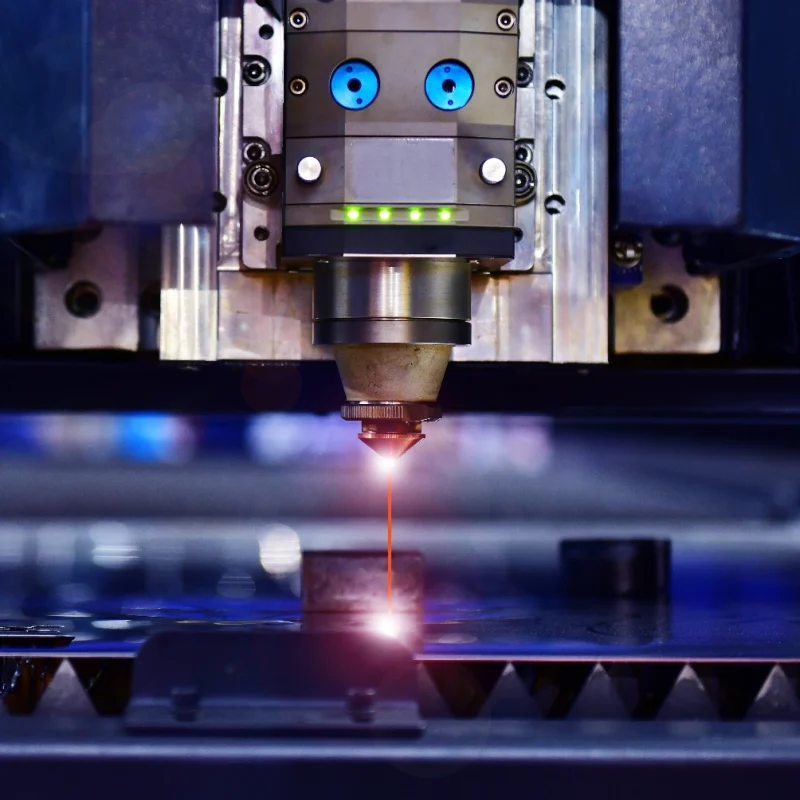

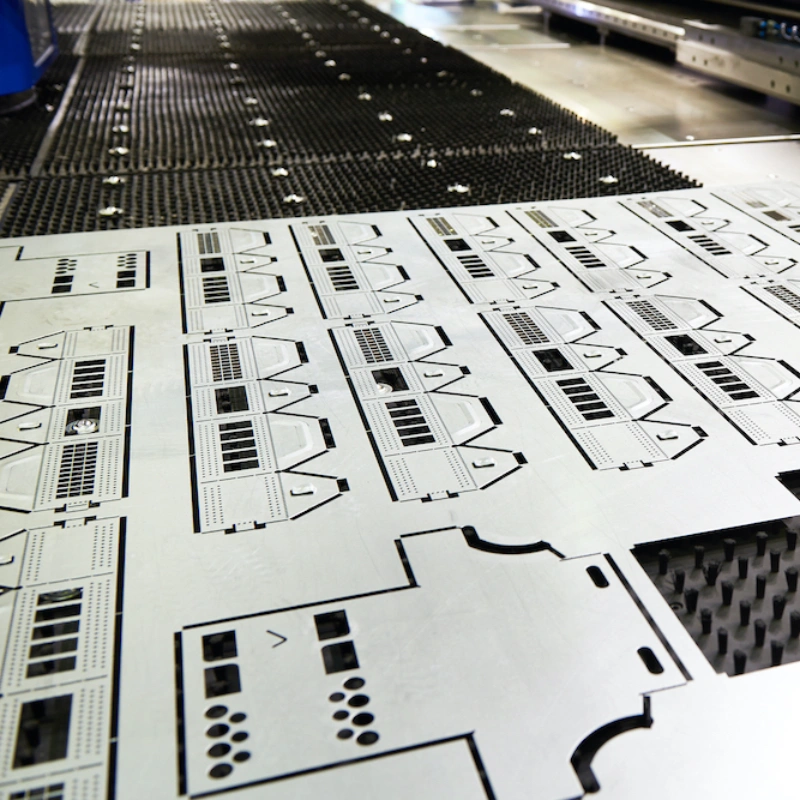

We choose Precision Sheet Metal Fabrication (e.g., CNC Punching/Bending, Laser Cutting), which offers excellent flexibility, quick turnaround for prototypes, and tight tolerances for custom shapes.

For Maximum Cost-Efficiency in High Volume

We utilize Sheet Metal Stamping for its speed, high repeatability, and lowest per-unit cost once the die investment is justified (typically millions of parts).

Why choose extrusion over other processes?

Advanced manufacturing processes, such as Extrusion and Stamping, are selected based on their ability to deliver cost optimization, high throughput, and uncompromising quality. These methods collectively ensure products are delivered with superior precision and maximum production efficiency.

1. Manufacturing Process Advantages (Efficiency & Quality)

These points describe the inherent benefits of the selected manufacturing methods:

- Single-Step Forming: Single-step forming minimizes secondary processing, resulting in Optimal Cost-Efficiency.

- High Throughput: High operational speed, often running 24/7, guarantees Sufficient Production Capacity.

- Ultimate Precision: Micrometer-level dimensional control ensures Worry-Free Assembly of final components.

Extrusion Process Flow

The preparatory phase involves selecting the correct aluminum alloy and homogenizing it for uniformity. The billet is then precision-cut, pre-heated to optimize plasticity (400-500℃), and thoroughly cleaned to prevent surface contamination and protect the extrusion die.

1.Raw Material Selection and Pre-Treatment Select aluminum billets (pure aluminum or alloy, e.g., 6063, 6061 series) based on the profile’s intended use, ensuring the composition meets requirements for strength, corrosion resistance, etc. Perform Homogenization (soaking at high temperature followed by slow cooling) to eliminate internal segregation and enhance material uniformity.

2.Billet Cutting and Machining Cut the aluminum ingot into billets of a fixed length using a sawing machine, matching the press container dimensions and single profile length requirement. Flatten the billet end faces (e.g., by turning) to prevent uneven stress application during extrusion.

3.Billet Heating (Pre-heating) Heat the cut billets in a furnace to $400-500^\circ\text{C}$ (temperature varies by alloy). Hold the temperature for a set time to ensure the internal temperature is uniform, enhance the aluminum’s plasticity, and reduce resistance to deformation during the pressing stage.

4.Surface Cleaning Remove surface scale, oil, or impurities (typically via grinding, acid pickling, or high-pressure air blast). This prevents contaminants from entering the press container or die, thereby protecting the profile’s surface quality and the die’s lifespan.

The critical second phase focuses on meticulous die preparation, beginning with detailed Die Design to define the profile’s cross-section, working dimensions (like bearing length), and complex features (e.g., ports for hollow profiles). High-strength H13 tool steel is then precision Machined (using CNC/EDM), polished to a low roughness, and heat-treated to ensure high hardness and wear resistance. Finally, the die undergoes Pre-Treatment by being pre-heated to match the billet temperature (300-400℃), receiving surface treatments (nitriding/coating) to enhance lubrication, and passing a final inspection for dimensional accuracy and surface quality before deployment.

1.Die Design and Parameter Determination Based on the profile’s cross-sectional shape, dimensional tolerances, and wall thickness distribution, create 3D die drawings to define the dimensions of the core, casing (mandrel/sleeve), and flow structures. Calculate critical parameters, such as the die entrance angle and bearing length, based on the aluminum alloy and extrusion speed, to ensure uniform metal flow. For complex profiles (e.g., hollow or irregularly shaped), design bridge ports and welding chambers to ensure smooth billet formation and secure weld seams.

2.Die Machining and Manufacturing Select high-strength tool steel (e.g., H13 steel) and precisely machine the die cavity and bearing surface using processes like CNC milling and Electrical Discharge Machining (EDM). Polish the die bearing surface to achieve a low roughness level, preventing scratching of the profile surface. After machining, perform Heat Treatment (quenching + tempering) to enhance the die’s hardness and wear resistance, thereby extending its service life.

3.Die Pre-Treatment and Inspection Pre-heat the die in a furnace before use, controlling the temperature to 300-400℃ to match the billet temperature and prevent thermal shock leading to die cracking. Apply surface treatments like nitriding or coating to enhance surface hardness and lubricity, reducing friction between the aluminum and the die. After pre-treatment, inspect the die for dimensional accuracy and surface finish, confirming it is free of cracks, burrs, or other defects before being approved for extrusion.

The crucial shaping stage, Core Extrusion Forming, begins with placing the pre-heated billet into the extrusion press container. A high-tonnage hydraulic ram then applies immense pressure (up to several thousand tons), forcing the billet to undergo plastic flow. This pressure pushes the softened metal through the prepared die opening, forming a continuous profile section (extrudate) with the desired cross-sectional shape. This operation is predominantly executed using the direct extrusion method.

Billet Loading: The pre-heated, plastic aluminum billet is rapidly loaded into the press container (cylinder).

High-Pressure Application: The ram applies tremendous force (several thousand tons) onto the billet.

Plastic Flow and Forming: Under high pressure, the billet undergoes plastic flow and is forced through the die opening, where it takes the shape of the desired cross-section.

Continuous Profile Output: This action results in the formation of a continuous profile section (extrudate).

The high-temperature aluminum profile, emerging from the press at approximately 400℃, is uniformly covered and cooled using either air cooling (with an air speed of $5-10 m/s or water cooling (using water at 20-30℃. The profile temperature is quickly reduced to 120-150℃ within 30-60 seconds, with parameters constantly monitored and adjusted in real-time. This rapid solidification ensures dimensional accuracy and optimal material performance.

1.Cooling Pre-Setup Adjust the distance between the cooling equipment (air fans, water spray devices) and the profile exit to ensure the entire profile surface is covered with no dead zones. Set cooling parameters: For air cooling, adjust to the appropriate speed (typically 5-10 m/s); for water cooling, control water temperature 20-30℃ and pressure to prevent strong water impact on the profile.

2.Cooling System Activation Immediately activate the cooling equipment after the profile exits the die, ensuring synchronization between cooling and extrusion to avoid any “cooling lag.” Air Cooling: Use multiple fan sets to create a continuous, uniform airflow across the top, bottom, and side surfaces of the profile to prevent localized rapid cooling that could cause deformation. Water Cooling: Employ spraying or mist cooling to uniformly cover the profile surface (avoiding direct high-pressure streams to prevent profile cracking), while simultaneously and quickly draining hot water to maintain cooling efficiency.

3.Continuous Cooling and Temperature Monitoring The profile moves continuously through the cooling channel, with the cooling duration controlled to 30-60 seconds (adjustable based on wall thickness; thinner profiles may require less time). Use an infrared thermometer to monitor the profile exit temperature in real-time, ensuring the final temperature drops to 120-150℃ for preliminary setting of the shape.

4.Post-Cooling Initial Inspection Check the profile surface for condensation, watermarks (must be blown dry immediately after water cooling), or localized deformation. If bending occurs due to non-uniform cooling, immediately adjust the cooling equipment angle or airflow/water pressure to ensure consistent cooling effects for subsequent profiles.

Surface Cleaning involves removing the oxide scale, oil, and impurities from the billet surface using methods such as grinding, acid pickling, or high-pressure air blast. This is done to prevent contaminants from entering the press container and the die, thereby safeguarding the profile’s surface quality and extending the lifespan of the die.

1.Pre-Cleaning Preparation Inspect the billet surface to determine the degree of adherence of oxide scale, oil, and impurities, and select the corresponding cleaning method (High-pressure air for light impurities, grinding for heavy oxide scale, electrolytic pickling for heavy oil contamination). Prepare tools/materials: Grinding machine, acid pickling tank (containing acid and neutralizing solutions), high-pressure air gun, and drying equipment, ensuring the equipment is functional and material concentrations are compliant.

2.Targeted Cleaning Operations Grinding: Gently polish the billet surface with an angle grinder or belt sander, focusing on removing raised oxide scale and stubborn impurities, avoiding over-grinding that could damage the billet body. Acid Pickling: Immerse the billet in the acid solution for a specified time (typically $5-10$ minutes) to dissolve oxide scale and oil, then immediately transfer it to a neutralizing solution to counteract residual acid. High-Pressure Air Blast: Uniformly sweep the billet surface with a high-pressure air gun to remove dust, fine impurities, and residual debris, suitable for light cleaning or as a finishing step after grinding/pickling.

3.Rinsing and Drying Billets subjected to acid pickling must be rinsed repeatedly with clean water to ensure no acid residue remains, preventing subsequent oxidation or corrosion. Use hot air or drying equipment to thoroughly dry the billet surface, avoiding moisture retention that could lead to secondary oxidation.

4.Cleaning Quality Inspection Visually inspect the billet surface to confirm the absence of oxide scale, oil, or impurity residues, and ensure there are no noticeable scratches or damage. Once approved, promptly transfer the billet to the next process (heating or extrusion) to prevent re-oxidation from prolonged air exposure.

Metal Enclosure Manufacturing Process Comparison

| Comparison Dimension | Extrusion | Die Casting | Forging | CNC Precision Machining |

|---|---|---|---|---|

| Production Efficiency | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐ |

| Cost (Mass Production) | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐ |

| Accuracy Level | ±0.5mm | ±0.3mm | ±1mm | ±0.1mm |

| Material Utilization Rate | 70% | 60% | 50% | 30% |

| Irregular Section Capacity | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐ | ⭐⭐⭐ |

| Strength Performance | ⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ |

| Mold Cost | Medium | Low | High | None |

| Payback Period | 1-2 Years | 0.5 Years | 2-3 Years | None |

| Comprehensive Score | 9.0 | 8.5 | 7.5 | 8.0 |