Custom CNC Milling Services

On-demand CNC milling services for rapid prototypes and production parts. High precision CNC milling up to 0.008 mm. Milled parts ready in as fast as 1 day. Get an instant CNC quote today.

Online CNC Milling Services for Custom Parts

From 3-axis basics to intricate 5-axis projects, our precision CNC milling makes your designs come alive with unmatched accuracy and craftsmanship.

3-Axis CNC Milling

With 3-axis CNC milling, precision meets affordability. It’s your go-to for simple parts that still demand accuracy.

4-Axis CNC Milling

Think of a design, and 4-axis milling can probably make it. Multi-sided machining just got a whole lot simpler.

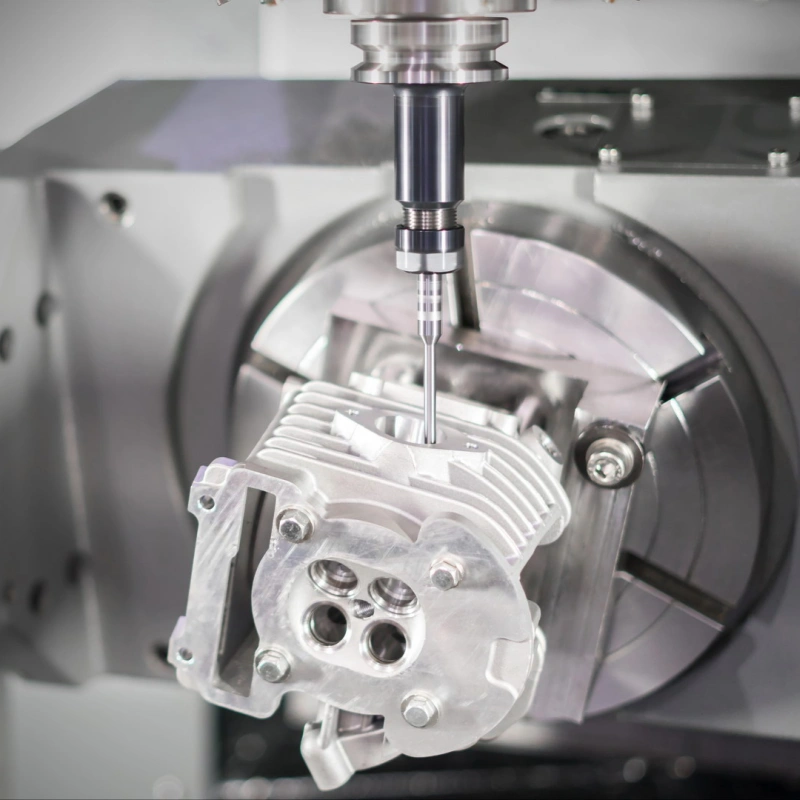

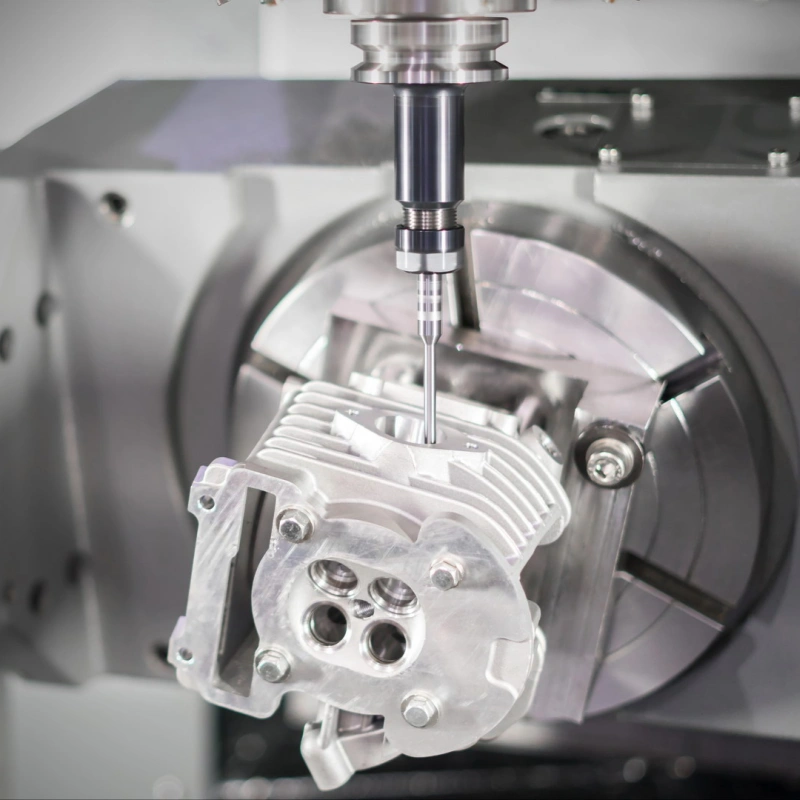

5-Axis CNC Milling

For those complex and intricate parts, 5-axis milling is the master key. Bring your most ambitious designs to life.

CNC Machining Solutions

Rapid Prototyping

Accelerate product development with our rapid CNC machining services. We offer fast turnaround times and specialize in quick production of high-quality prototypes and mold tooling, aiding your design verification process.

Low and High-Volume Production

Whether you need small batches or large-scale production, we can offer you both. With stringent tolerance controls and comprehensive capabilities, we adapt to your volume requirements without compromising on quality.

CNC Milling Materials

At RapidDirect, our plastic and metal CNC milling solutions offer a diverse range of materials, ensuring precision and durability. This vast selection empowers our clients with optimal choices for their unique projects, boosting their product’s quality and performance.

- Aluminium

- Steel

- Stainless Steel

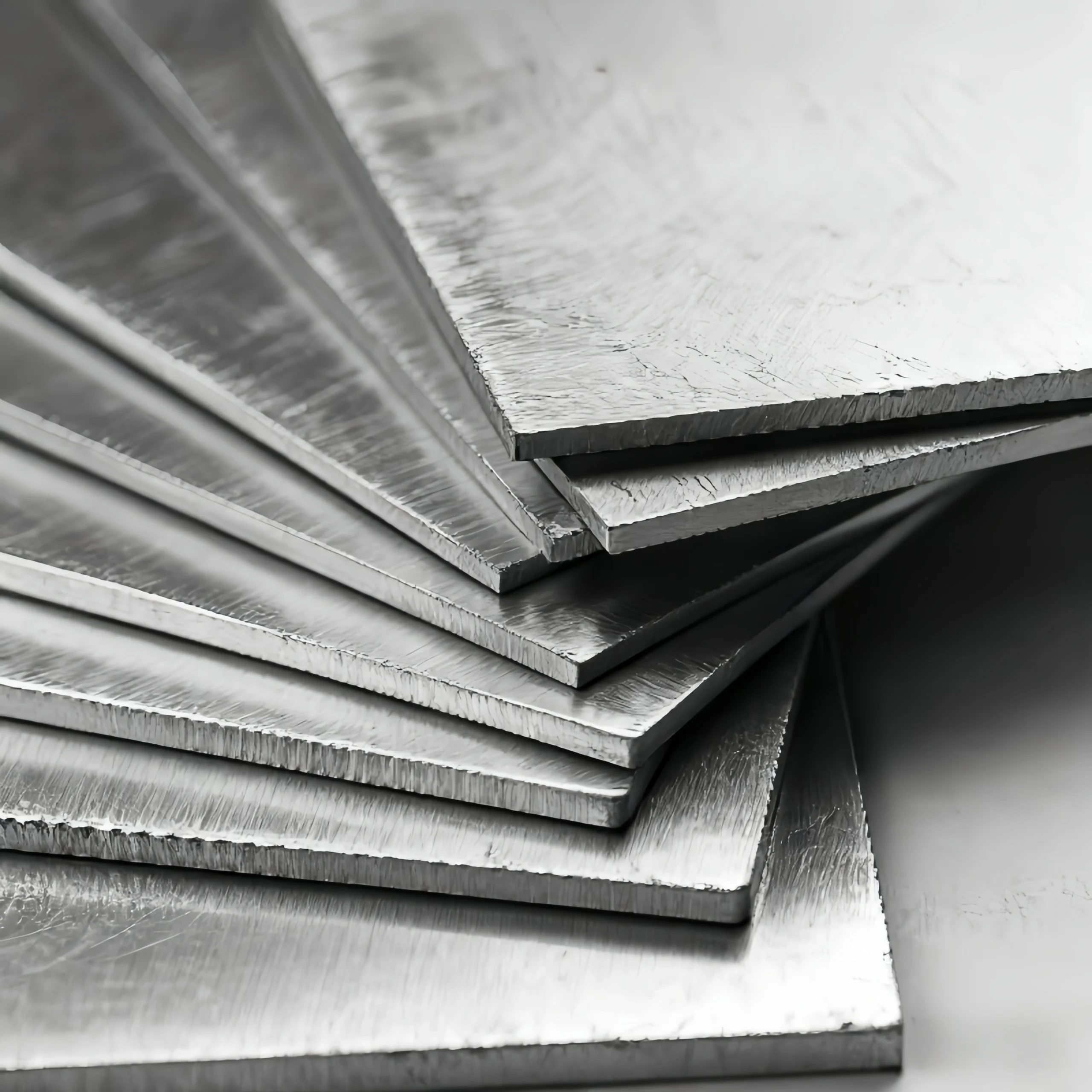

Aluminium

Aluminium is lightweight, strong, and easy to machine, positioning it great for various applications like aerospace and automotive parts. Its corrosion resistance also adds to its appeal in outdoor projects and structural components.

Color: Silver

Subtypes: Aluminium 6061, 6061-T6, Aluminium 2024

Available Finish: As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

Price: $$

Lead Time: About 5 business days

View More

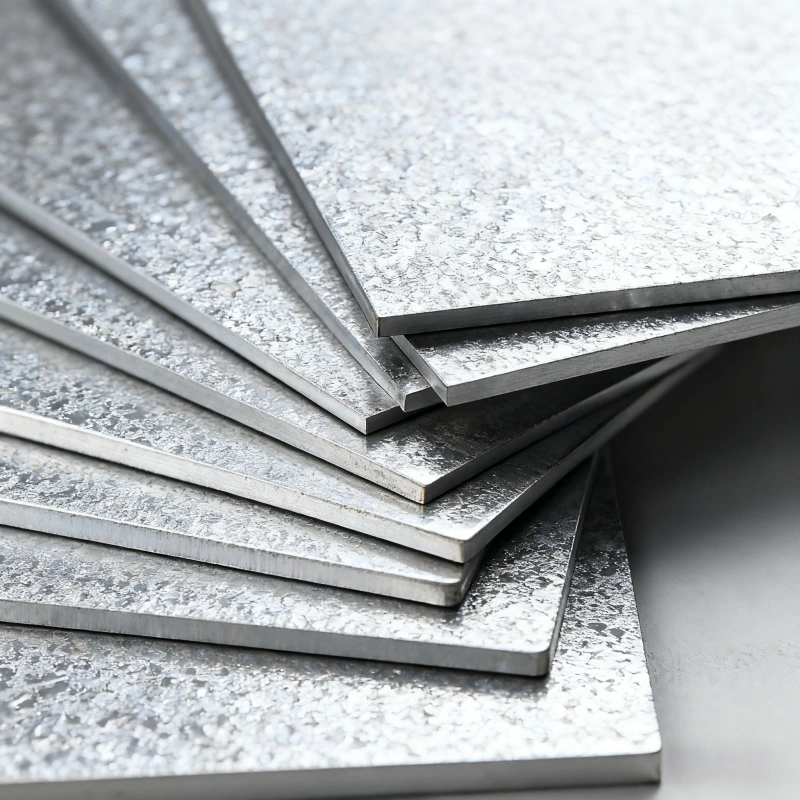

Steel

Steel is an alloy of iron and carbon, known for its high tensile strength and durability. It's widely used in construction, manufacturing, and automotive industries due to its versatility and cost-effectiveness.

Color: Dark Gray

Subtypes: Carbon Steel, Alloy Steel, Tool Steel

Available Finish: As rolled, Galvanized, Painted, Powder coated, Polished

Price: $

Lead Time: About 3-5 business days

View More

Stainless Steel

Stainless steel is an alloy of iron, chromium, and other elements, prized for its corrosion resistance and sleek appearance. It's commonly used in kitchenware, medical equipment, and architectural applications.

Color: Silver

Subtypes: 304, 316, 430, 17-4 PH

Available Finish: Brushed, Mirror, Satin, Bead blasted, Anodized

Price: $$$

Lead Time: About 5-7 business days

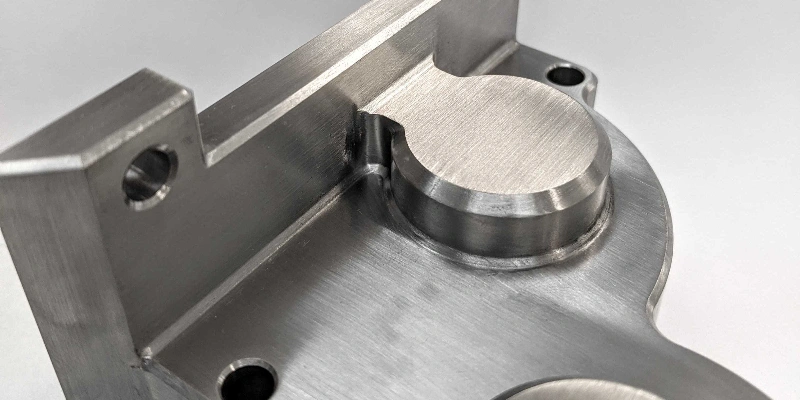

View MoreCNC Milling Surface Finishes

Gain access to quality surface finishing for custom CNC milled parts to remove aesthetic flaws and improve the appearance of your products. We also provide rigid protection and additional resistance and strength to your parts through superior surface finishes.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

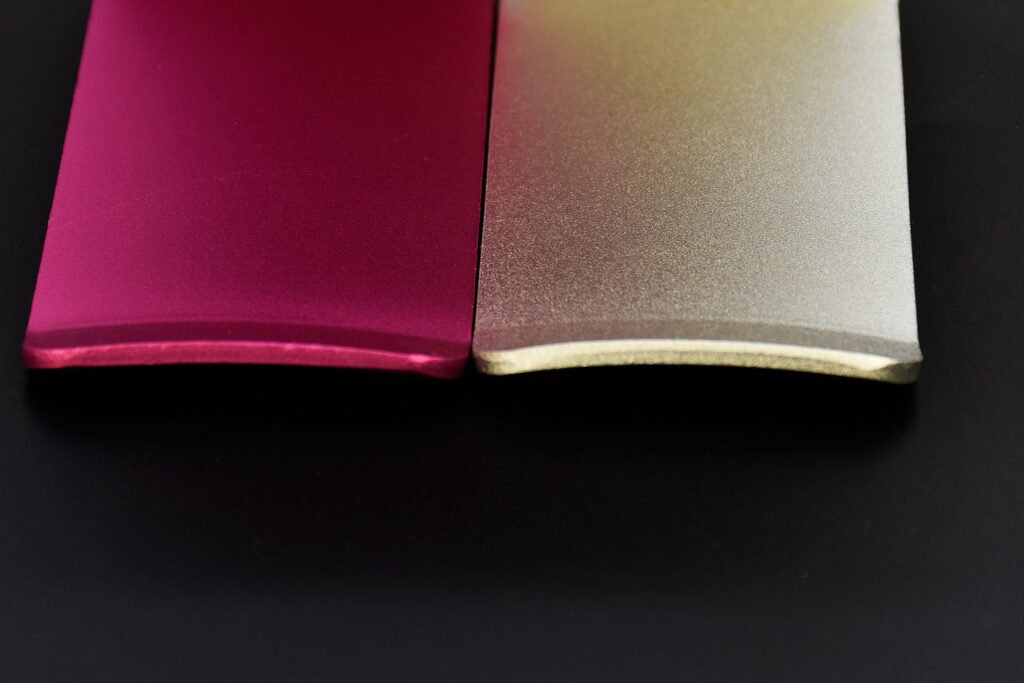

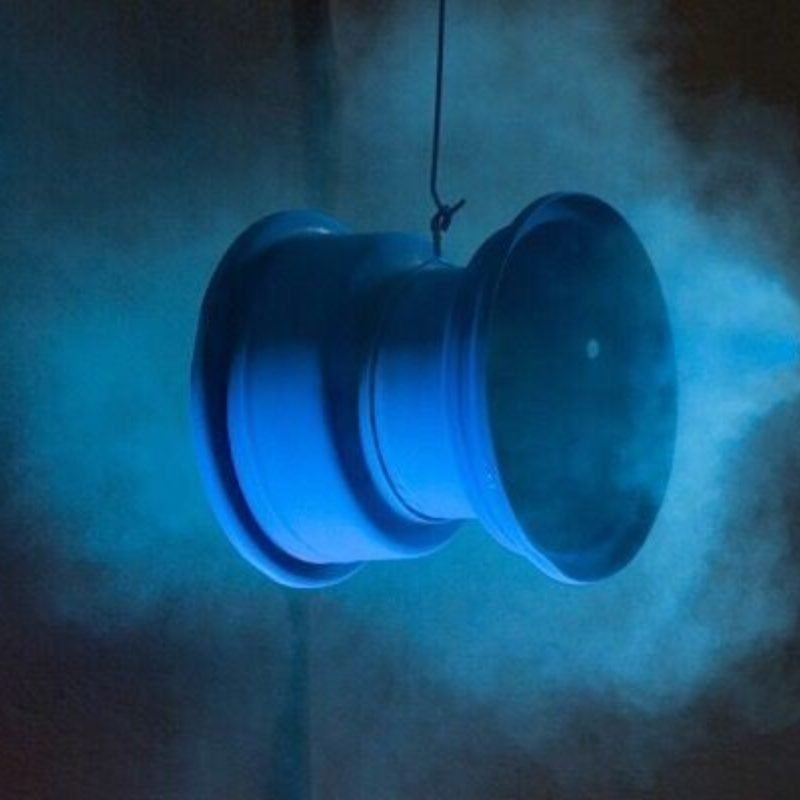

Anodizing

2-1024x685.png)

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

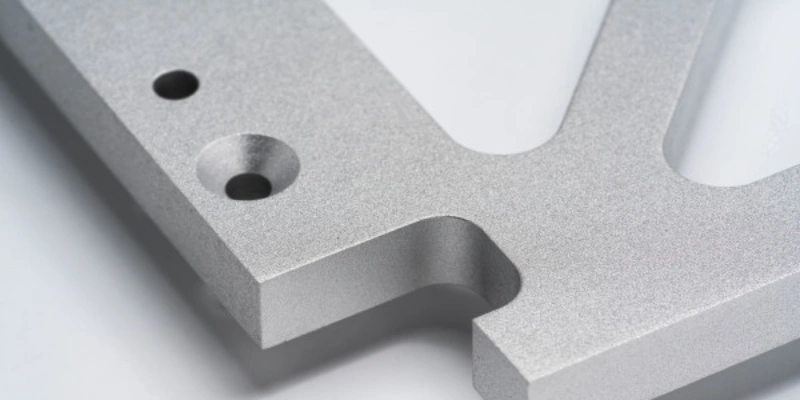

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

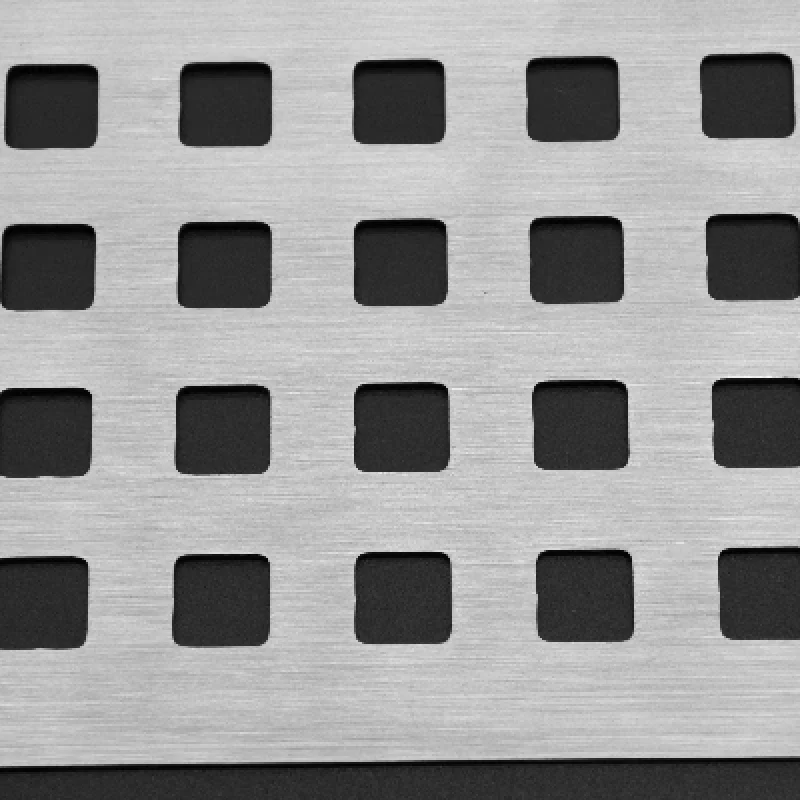

Brushed Finish

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder Coating

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Black Oxidize

Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection.

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Tolerances for CNC Milling

CNC Milling

RapidDirect ensures precision with our CNC Milling Tolerance standards. We commit to exact measurements, benefiting clients with consistent, high-quality results, optimized for search visibility. Our standard tolerances for CNC milled metals are ISO 2768-m and ISO 2768-c for plastics.

| Machine Type | Maximum Part Size (mm) | Minimum Part Size (mm) | General Tolerances (mm) | Lead Time |

|---|---|---|---|---|

| 3-Axis | 1000 x 500 x 500 | 5 x 5 x 5 | ±0.1 | Delivery of simple parts can be as fast as 1 day. |

| 4-Axis | 1000 x 500 x 500 | 5 x 5 x 5 | ±0.1 | 5 business days for most projects. |

| 5-Axis | 4000×1500×600 | 5 x 5 x 5 | ±0.05 | 5 business days for most projects. |

Why Choose Us

With Tongchengjianhui’s CNC milling service online, you’re investing in more than just machinery. You get the promise of impeccable precision, adherence to tight schedules, and the support of seasoned professionals for all your custom CNC milling needs.

High Quality Parts

Experience unparalleled precision in each undertaking. Our advanced milling processes ensure components adhere to tight tolerances, as tight as ±0.01mm, resulting in seamless assembly and operational excellence.

Fast Lead Time

Accelerate your manufacturing cycle. RapidDirect domestic workshops and state-of-the-art machinery guarantee fast turnaround times, helping businesses maintain momentum and meet critical deadlines.

Engineering Support

No matter you whenever and whereever, navigate your CNC milling projects with confidence. Our seasoned specialists offer insightful guidance at every step, maximizing design optimization and output quality.

How CNC Milling Works?

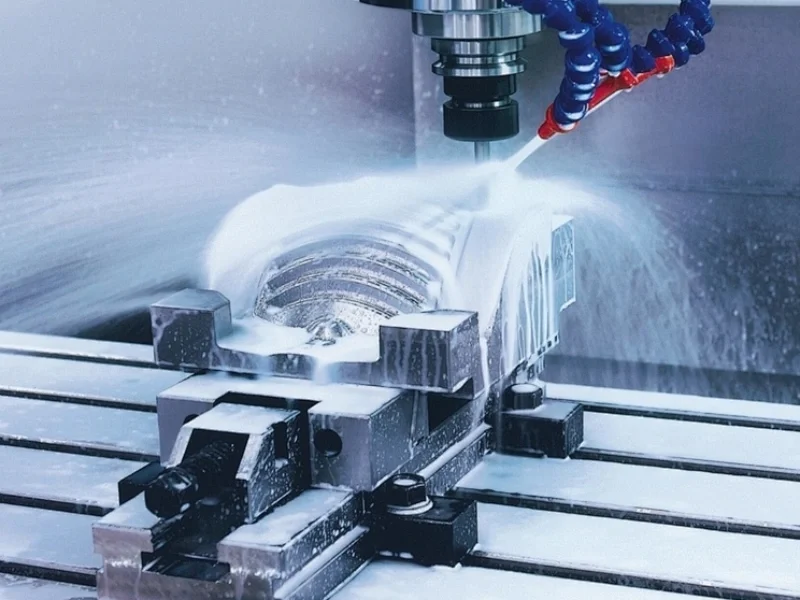

CNC milling is a precise manufacturing process that involves removing material from a workpiece using rotating cutting tools. The process begins with a digital design, typically created in CAD software. This design is then converted into a CNC program, which dictates the movements of the milling machine.

The workpiece is securely fastened to the machine’s table, and the cutting tool, mounted on a spindle, rotates at high speeds. The machine follows the programmed path, making precise cuts to shape the material into the desired form. CNC milling can create complex shapes and features, such as slots, holes, and contours, with high accuracy.

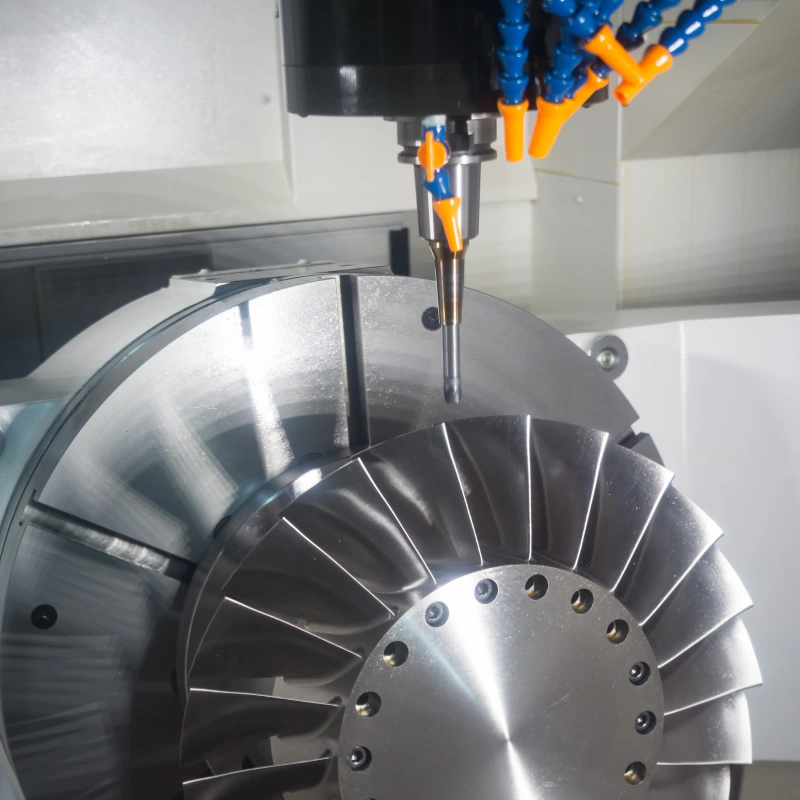

Three-axis milling moves the tool along the X, Y, and Z axes. Four-axis milling adds rotation around one axis, while five-axis milling allows rotation around two axes, enabling more intricate designs. This versatility makes CNC milling essential in various industries, from aerospace to medical devices.