Custom Metal Enclosure Services

Upload your design file to get started and receive an instant quote for a custom metal enclosure.

- Precision quality with 3-day lead time

- 10+ Finish options

- ISO 9001:2015, ISO 13485, ISO14001:2015, certified

Start New Metal Enclosure Project

Custom Metal Enclosure Fabrication Services

With over 30 advanced machines, like laser cutters, bending machines, and welders, in our China-based network, we can supply any quantity of sheet metal parts, from low-volume prototypes to high-volume production. Our domestic fabricators and engineers provide precision and fast delivery.

Extrusion

Extrusion uses extruders to melt materials, push through dies into forms, with continuous production, low cost.

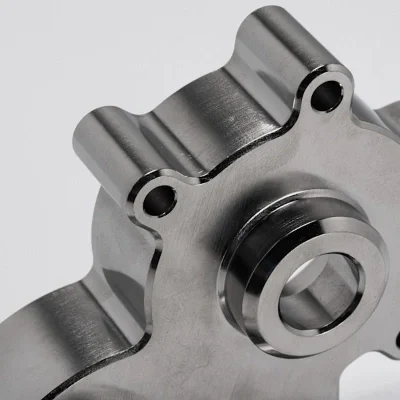

CNC Machining

CNC uses computer-controlled machines to shape materials, with high precision, automation, good for complex parts.

Stamping

Stamping uses presses and dies to press flat metal at normal temp, deform/separate it into 3D parts, with fast mass production, high precision, low cost.

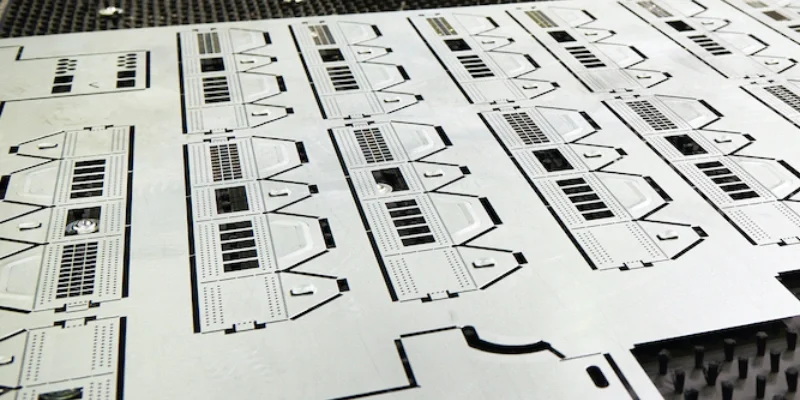

Laser Cutting

Laser cutting uses lasers to cut materials with high heat (melting/vaporizing them) into needed shapes, and has fast speed, precision, smooth cuts and suitability for many materials.

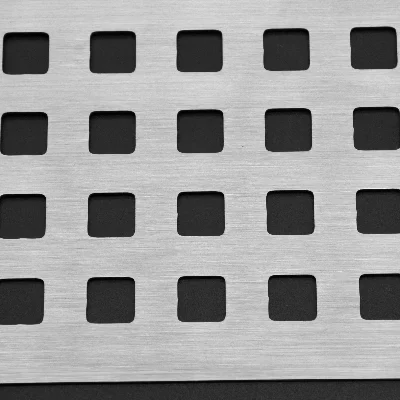

Punching

Punching uses presses and dies to press materials for holes at normal temp, with fast speed, precision, good mass production fit and neat edges.

Riveting

Riveting uses rivets and pressure to join workpieces, with strong joints, easy operation, good for many materials and no welding.

Bending

Bending uses bending machines and dies to press flat metal at normal temp, bend it into shapes, with high precision, good mass production, low cost.

Welding

Welding uses heat to join metal parts, with strong joints, fits many metals, low cost.

Surface Finishing Options for Metal Sheets

Enhance the durability and appearance of your custom metal parts with our range of surface finishing options. For special requirements, our engineering team will work with you to develop a tailored solution.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing

2-rd6ajjt26rzza0a7ni4t3snppztve2t32h4kot2en4.png)

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

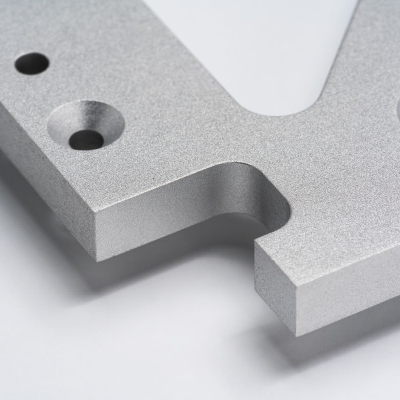

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

Brushed Finish

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder Coating

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Black Oxidize

Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection.

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

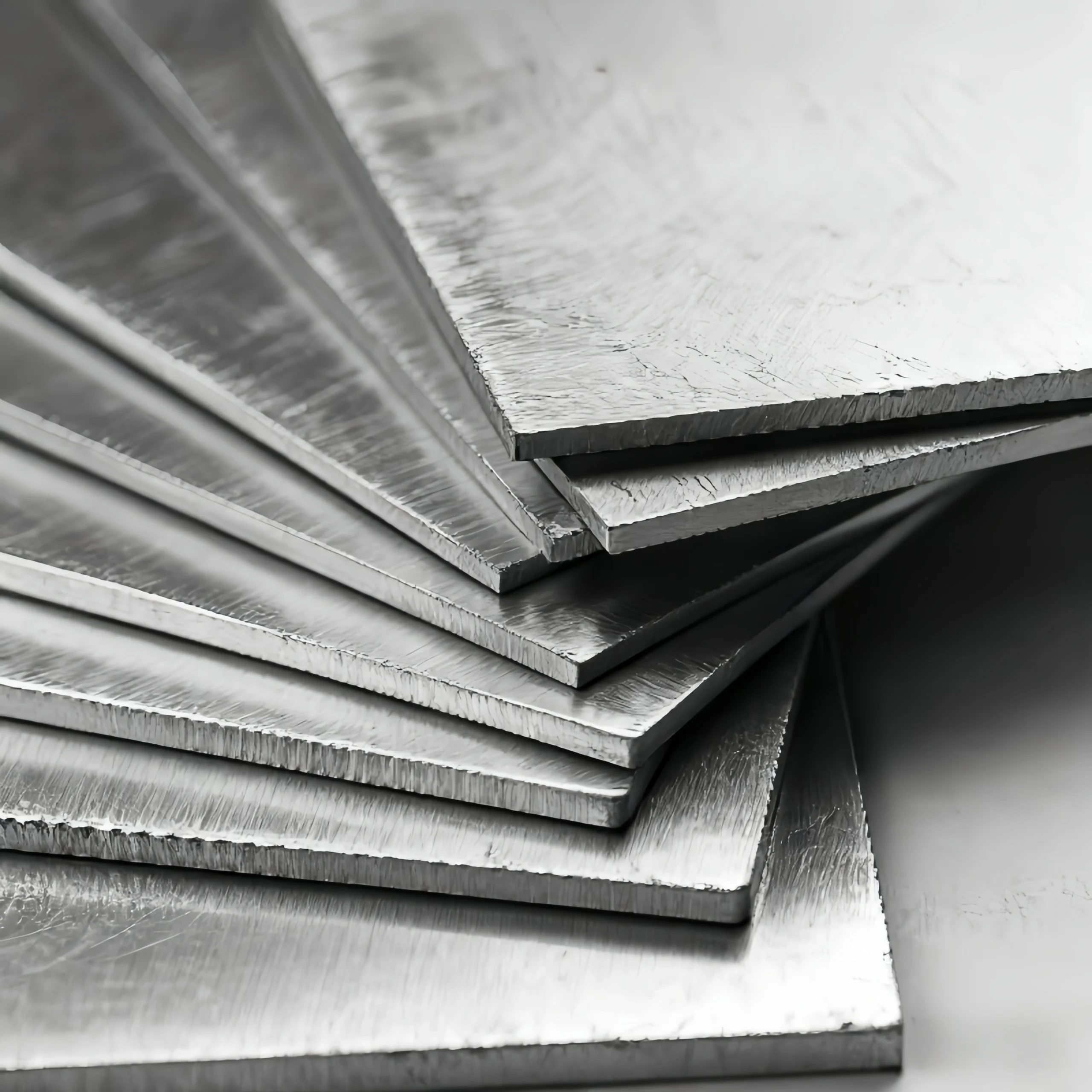

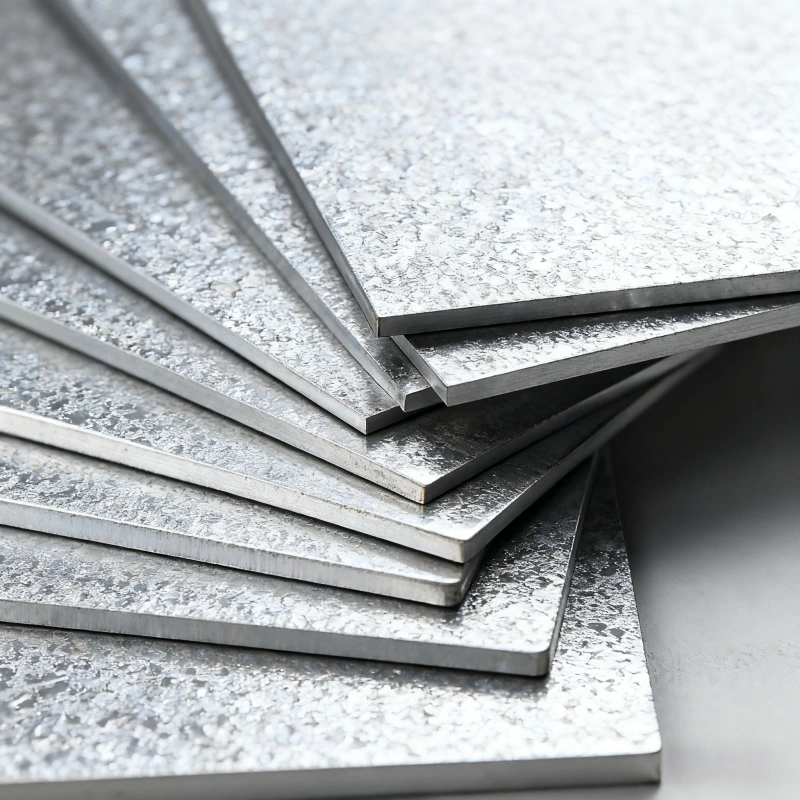

Metal Enclosure Materials We Excel In

Using a combination of CNC machining and stamping dies, we specialize in producing custom metal enclosures from materials like galvanized steel and aluminum alloys, particularly the 6063 and 5052 series.

- Aluminium

- Steel

- Stainless Steel

Aluminium

Aluminium is lightweight, strong, and easy to machine, positioning it great for various applications like aerospace and automotive parts. Its corrosion resistance also adds to its appeal in outdoor projects and structural components.

Color: Silver

Subtypes: Aluminium 6061, 6061-T6, Aluminium 2024

Available Finish: As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

Price: $$

Lead Time: About 5 business days

View More

Steel

Steel is an alloy of iron and carbon, known for its high tensile strength and durability. It's widely used in construction, manufacturing, and automotive industries due to its versatility and cost-effectiveness.

Color: Dark Gray

Subtypes: Carbon Steel, Alloy Steel, Tool Steel

Available Finish: As rolled, Galvanized, Painted, Powder coated, Polished

Price: $

Lead Time: About 3-5 business days

View More

Stainless Steel

Stainless steel is an alloy of iron, chromium, and other elements, prized for its corrosion resistance and sleek appearance. It's commonly used in kitchenware, medical equipment, and architectural applications.

Color: Silver

Subtypes: 304, 316, 430, 17-4 PH

Available Finish: Brushed, Mirror, Satin, Bead blasted, Anodized

Price: $$$

Lead Time: About 5-7 business days

View MoreMetal Enclosure Fabrication Capabilities

| Desctription | |

|---|---|

| General Tolerances | Metals : ISO 2768-c |

| Cutting Feature | ±0.002mm |

| Bend Angle | ±0.25° |

| Bend to Edge | ±0.1mm |

| Bend to Hole | ±0.1mm |

FAQS

How do I get started with my sheet metal project?

How much does sheet metal fabrication cost?

Is there a minimum order quantity for fabrication services?

At Tongcheng Jianhui, we support projects of all sizes. We accommodate both small and large production runs, offering our services for everything from a single prototype to mass production. Importantly, we do not enforce a strict minimum order quantity. This flexibility allows customers, whether startups or large corporations, to leverage our sheet metal fabrication services tailored to their specific needs and scales.

Differences Between 6063, 6061, and 5052 Aluminum for Enclosures

Summary

- If your project requires a beautifully finished enclosure with complex extruded profiles, and strength is not the primary concern, choose 6063.

- If you need a strong, durable enclosure that requires extensive CNC machining, choose 6061.

- If you need a complex shape formed by stamping or bending, and superior corrosion resistance, choose 5052.

These three aluminum alloys are common materials for manufacturing metal enclosures, but each has a distinct focus on processing methods and final product characteristics. Choosing the right material depends on your project’s specific requirements for aesthetics, strength, and forming process.

Manufacturing Differences

- 6063 Aluminum: Best suited for extrusion and anodizing. Its excellent extrudability makes it easy to create profiles with complex internal features (like heat sinks). While it achieves a great surface finish, its lower strength makes it less ideal for extensive milling.

- 6061 Aluminum: An extremely versatile alloy and the top choice for CNC machining. It has excellent workability, weldability, and medium-to-high strength, making it ideal for enclosures that require intricate milling, drilling, and other complex machine operations.

- 5052 Aluminum: The best choice for sheet metal fabrication. As a non-heat-treatable alloy, it has superior cold formability, making it perfect for stamping, bending, and deep drawing to create seamless, complex enclosure shapes.

Final Product Differences

- 6063 Aluminum: The final product is known for its aesthetics and lightweight feel. The surface finish after anodizing is exceptional, making it a favorite for consumer electronics, decorative enclosures, and lighting fixtures.

- 6061 Aluminum: The final product is defined by high strength and durability. It provides robust structural support and impact resistance, making it the ideal choice for industrial equipment, automotive parts, and any functional enclosure requiring high strength.

- 5052 Aluminum: The final product is valued for its excellent corrosion resistance and complex shapes. It is especially well-suited for devices used in outdoor, humid, or marine environments, such as street signs, communication equipment housings, and boat components.

6063-T3 vs. 6063-T5 for Enclosure Manufacturing

Summary

- If you need a visually appealing and cost-effective enclosure with complex extruded shapes, and maximum strength is not a concern, 6063-T5 is the ideal standard choice.

- If you require an enclosure with maximum hardness and rigidity to withstand high stress or impact, and your design does not involve complex bends, 6063-T3 can provide superior durability.

For the vast majority of aluminum enclosure projects, T5 is the standard and most reliable solution.

6063-T5: The Standard Choice

Manufacturing Process: The T5 temper involves cooling the metal after extrusion and then performing artificial aging. This process achieves a good balance of strength and formability.

Pros:

- Balanced Properties: T5 provides enough strength for most enclosure applications while maintaining good ductility. This makes it a reliable choice for general-purpose parts.

- Cost-Effective: As the standard temper for 6063 extrusions, T5 is highly efficient to produce, readily available, and more affordable, making it the most economical option for mass production.

- Dimensional Stability: The aging process minimizes internal stress, so the material is less likely to warp or deform during and after CNC machining, which is crucial for precision parts.

Cons:

- Lower Hardness: Compared to T3, T5 is less hard, making it more susceptible to scratches and dents in high-wear or impact-prone environments.

6063-T3: The High-Strength Alternative

Manufacturing Process: The T3 temper involves solution heat treatment followed by a cold-working step (like stretching or drawing) and then natural aging. This cold-working process is the key difference.

Pros:

- Higher Strength and Hardness: The cold-working step significantly increases the alloy’s tensile strength and surface hardness. If your enclosure needs to withstand heavy loads or require superior durability, T3 is a better choice.

Cons:

- Reduced Formability: The increased hardness makes the material less ductile. It is more difficult to bend or form into complex shapes without cracking.

- Higher Cost: The T3 process is less common and involves an extra manufacturing step, making it more expensive and less readily available than T5.

- Potential for Internal Stress: The cold-working can introduce internal stress, which might lead to slight warping after cutting or machining, potentially affecting the precision of the final part.