TCJH Metal Parts is pleased to offer a full range of ISO 9001:2015 certified manufacturing services, from precision metal stamping to tooling and laser cutting. Whatever your needs, we have the knowledge, experience, and equipment to design and fabricate custom metal parts, components, and finished products. We specialize in turnkey packages, and our dedicated staff work directly with your engineers, designers, and specialists to ensure that your product is fabricated with the utmost precision.

Metal Parts Served Industries

Work with a company that you can trust

We have obtained ISO 9001, BSCI, and SGS certifications.

Custom Metal Parts by Industries

These four manufacturing processes—stamping, sheet metal fabrication, extrusion, and CNC machining—are used to produce various types of casings and parts, each with unique strengths. Stamping is best for high-volume, cost-effective production of consistent parts, widely used in the automotive and electronics industries. Sheet metal is ideal for creating large, durable, and customizable enclosures for industrial and communication equipment. Extrusion is highly efficient for manufacturing lightweight parts with excellent thermal conductivity, often found in consumer electronics and LED lighting. Finally, CNC machining is the go-to process for high-precision, complex parts in small batches, critical for aerospace, medical devices, and high-end electronics.

CNC Machining

CNC machining uses computer-controlled machines to precisely cut a solid block of material into the desired shape.

Key Industries: Aerospace (for high-precision aircraft parts), high-end electronics (for smartphone and drone casings), and military equipment.

Advantages: It provides extremely high precision and surface quality, is flexible for low-volume production without the need for molds, and can work with a wide range of materials.

Extrusion

Extrusion is a process where a heated material, typically aluminum, is pushed through a die to create a profile with a specific cross-sectional shape.

Key Industries: Consumer electronics (for laptop and tablet casings), transportation (for automotive and rail components), and LED lighting (for heat sinks and lamp bodies).

Advantages: Extrusion offers a high strength-to-weight ratio, excellent thermal conductivity, and high material efficiency, making it ideal for creating parts that require heat dissipation.

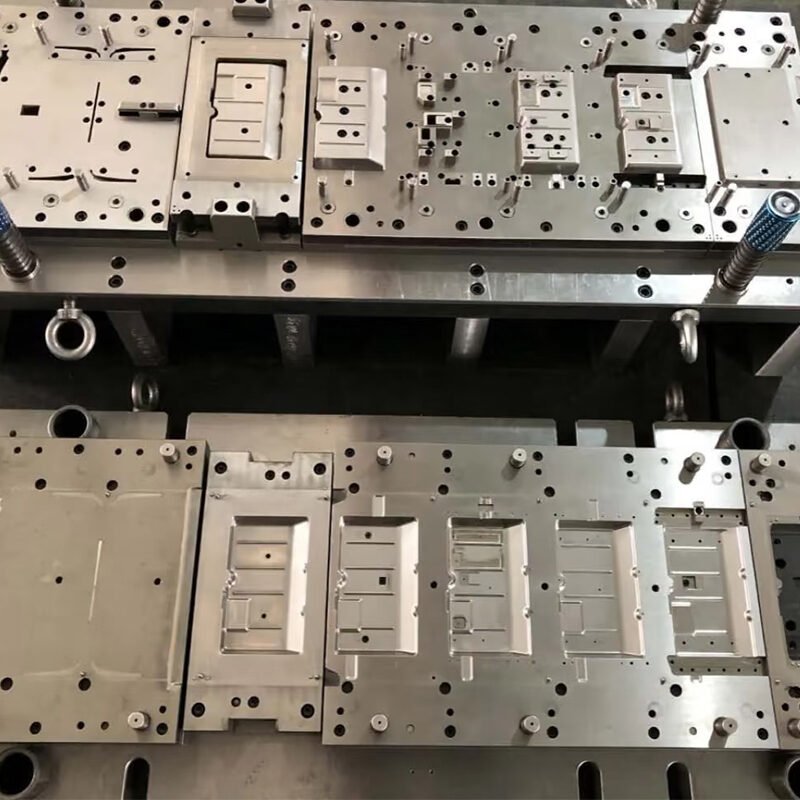

Stamping

Stamping, also known as press forming, is a widely used manufacturing process that is fundamental to many industries, particularly those requiring the mass production of metal parts with high precision and consistency.

Key Industries: Automotive (for car body panels), electronics (for shielding cases), aerospace (for high-strength components), and general hardware.

Advantages: Stamping excels at high-volume, low-cost production while maintaining a lightweight design, high material utilization, and consistent quality.

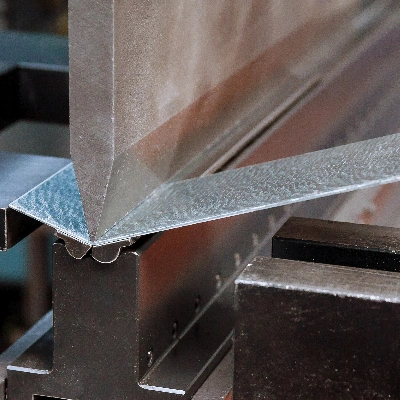

Sheet Metal

Sheet metal fabrication involves shaping thin metal sheets through cutting, bending, and welding.

Key Industries: Industrial control (for cabinets and enclosures), communications (for server racks and telecom shelters), and medical devices (for large equipment housings).

Advantages: It’s cost-effective for large-scale production, highly customizable, and provides excellent physical protection and electromagnetic shielding.

Precision Metal Forming Services

Tool & Die Design

Metal Stamping

Metal Bending