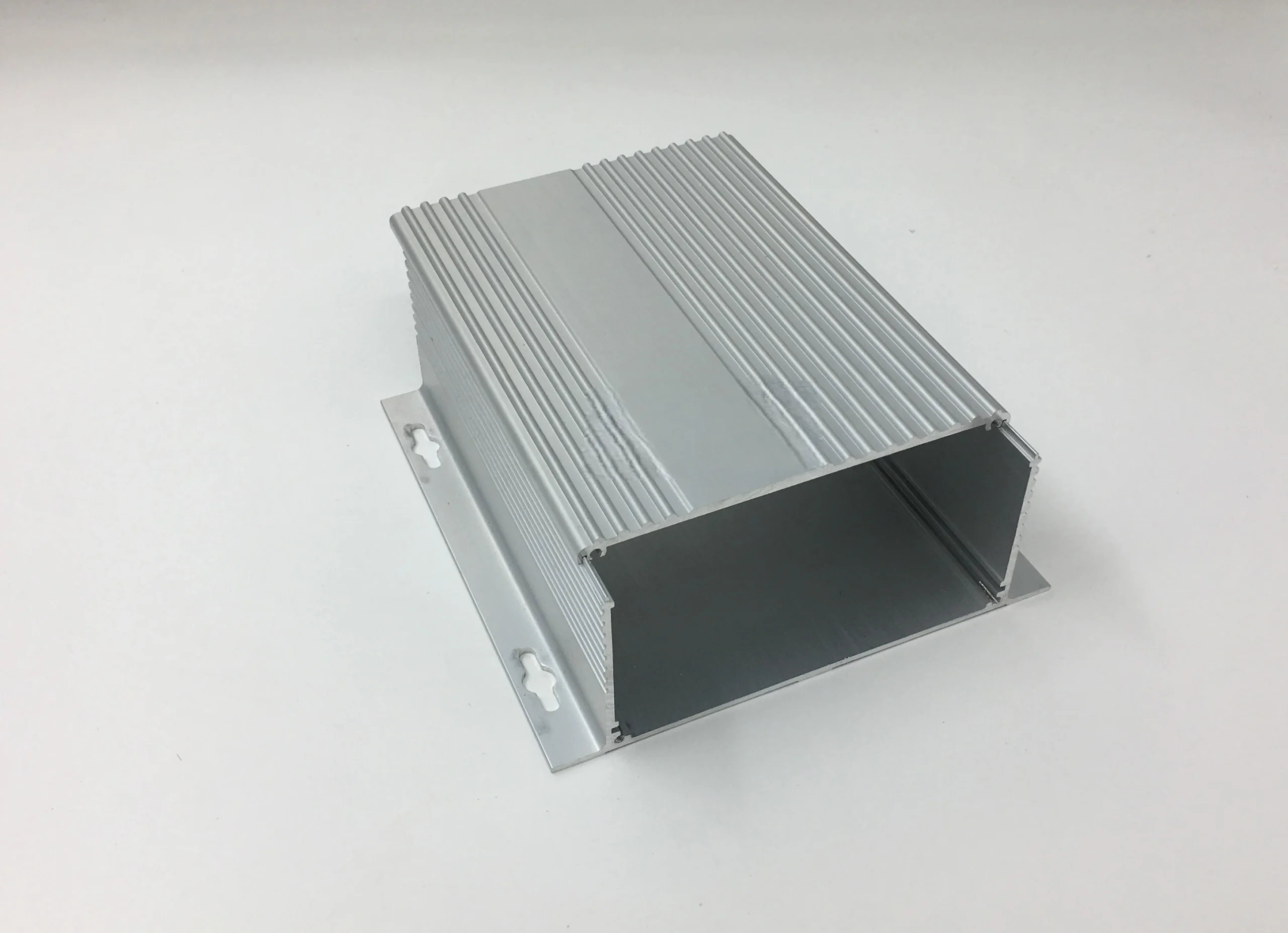

Aluminum enclosure -Industrial Power Enclosure

In the demanding world of industrial electronics, a simple case isn’t enough. You need an enclosure that does more than just protect—it needs to enhance performance and ensure reliability. The PowerCool Industrial Power Enclosure is engineered to be the silent guardian of your critical components, ensuring they perform flawlessly under pressure.

Key Features: Engineered for Tough Environments

Our enclosures are built to withstand the rigors of industrial applications. We use a high-precision extrusion process to create a single, seamless aluminum enclosure. This method allows us to craft intricate, integrated fins that are not just for show; they’re the core of the enclosure’s thermal management system. Unlike flimsy, folded metal boxes, our unified structure offers superior dimensional stability and a professional finish that signals quality.

At the heart of our design is a premium aluminum alloy, chosen for its outstanding thermal conductivity. This material acts as a massive, passive heatsink, efficiently drawing heat away from your power supplies and other high-heat components. By dissipating this heat into the ambient air, the enclosure keeps your electronics running at optimal temperatures without the need for noisy or failure-prone fans.

Beyond its thermal properties, this enclosure provides a rugged, protective shell. It’s strong, lightweight, and inherently corrosion-resistant, shielding your sensitive electronics from dust, moisture, and impact. This robust durability makes it the perfect solution for factory floors, control panels, and other harsh industrial settings.

Benefits: The PowerCool Advantage

- Superior Heat Dissipation: The advanced finned design, a direct result of the extrusion process, dramatically increases the surface area for heat exchange. This ensures your power supplies run cooler, which is critical for preventing thermal degradation and extending their operational lifespan.

- Enhanced Reliability: A cooler power supply is a more reliable one. By effectively managing heat, our aluminum enclosure allows your components to operate consistently at their peak performance, reducing the risk of unexpected failures and costly downtime.

- Robust Durability: This enclosure provides a fortress for your electronics, offering reliable protection against physical damage. You can trust that your devices are safe in any industrial environment.

- Streamlined Installation: The professional design not only looks great but is also built for easy integration into existing systems, whether it’s for a new build or an upgrade. The clean, uniform finish gives your entire setup a polished, professional appearance.

| Specifications | 61 x 147 x 155 mm |

|---|---|

| Material | 6063 Aluminum |

| Processing technology | surface oxidation treatment process |

| Application scope | Small Electronic Devices, Industrial Control Equipment, Instrumentation, Smart Home Devices |

Excellent Extrudability

6063-T5 aluminum is highly favored for its exceptional

Superior Corrosion Resistance

This alloy forms a dense, natural oxide layer that provides outstanding corrosion resistance against atmospheric conditions, water, and many chemicals. This makes it a perfect choice for outdoor or high-moisture environments. The corrosion resistance can be further enhanced with anodizing, which also allows for a variety of colors and finishes.

Application

Applications of Sheet Metal Enclosures

Sheet metal enclosures are primarily used to provide robust and durable protective casings for various electronic, mechanical, and electrical equipment. They play a critical role in numerous industries, including:

Electronics & Telecommunications: Used for casings of servers, networking devices, computers, and telecom base stations.

Industrial Automation: Serve as control cabinets and enclosures for industrial machinery and instruments, providing protection against harsh industrial environments.

Medical Devices: Offer enclosures that meet high standards for cleanliness and safety for diagnostic and monitoring equipment.

New Energy: Applied in devices like PV inverters, charging piles, and energy storage systems to withstand severe outdoor conditions.

Transportation & Security: Protect automotive electronics, railway signaling equipment, and security cameras.

Production and Delivery

Production and Delivery

How long does mold opening take?

15-25 days

How long does sampling take?

Samples are completed in 3-7 days.

How long does mass production take?

15-25 days

Supported Payment Methods

Supported Payment Methods

We support the following payment methods:

Trade Assurance

T/T (Telegraphic Transfer)

VTB (VTB Bank)

Offshore Account

About us

Xiamen Tongcheng Jianhui Industry and Trade Co., Ltd. is a high-tech enterprise specializing in the R&D, production, and sales of diverse electronic and electrical metal enclosures (such as chassis, cabinets, and cases for relays, routers, and industrial control) using a complete set of advanced processing equipment, including CNC punching, bending, and fiber laser cutting machines.

How to Order?

Step One

Send your Files and Request Signed NDA

Step Two

Engineering Analysis Send a Quotation

Step Three

Confirm the Order

Start Manufacturing

Step Four

100 % QC Inspection Machine Part

Step Five

Surface Treatment Feedback to Customer

Step Six

Shipping Feedback Tracking Number

Step Seven

After-sale service

Why Choose us?

With 21 years of experience in the metal parts manufacturing industry, our factory operates with a dedicated team of three professional engineers. We manage the entire production process in-house, from initial mold design and development to final surface treatment. Our comprehensive capabilities include laser cutting, welding, stamping, bending, and CNC machining, all backed by specialized teams, advanced machinery, and extensive expertise.

Comprehensive Metal Fabrication & Machining

We handle the entire production process in-house, from initial mold design and development to final surface treatment. Our comprehensive capabilities, backed by specialized teams, advanced machinery, and extensive experience, include laser cutting, welding, stamping, bending, and CNC machining.

Professional engineering team

We have a professional team of three engineers, all with master’s degrees and over 10 years of experience in mold design and metal manufacturing.

With 21 years of manufacturing experience

With 21 years of experience in the metal parts manufacturing industry, we are a seasoned company specializing in providing high-quality, precision-engineered products to our clients. Over two decades of expertise have allowed us to build a strong foundation of knowledge and exceptional production capabilities, enabling us to meet a wide range of complex design requirements. Our goal is to be a trusted partner for your business, delivering excellence through superior craftsmanship and reliable service.