| Name | Service | Applicable to | Machining marks | Cosmetic availability | Tolerances |

|---|---|---|---|---|---|

| As machined |

CNC machining,

Sheet metal fabricat ion |

Metals, Plastics | Visible, light surface scratches | No | Met after coating |

| Polishing | CNC machining | Metals | Removed on primary surfaces | Always cosmetic | Met after coating |

| Black oxide | CNC machining, Sheet metal fabrication | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible | No | Met after coating |

| Brushing | CNC machining, Sheet metal fabrication | Metals | Reduced for non-cosmetic, removed on primary surfaces for cosmetic | On request | Met after brushing |

| Bead blasting | CNC machining, Sheet metal fabrication | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic | On request | Not affected except for specific features* |

| Brushed + electropolishing | CNC machining 工 | Stainless steel | Removed on Primary surfaces | Always cosmetic | Met after electropolishing |

Note: The table data represents standard industry parameters and is subject to actual machining requirements and equipment accuracy.

Cosmetic finishes

Surface finishes can serve either a functional or aesthetic purpose. Surface finishes that serve both purposes are deemed cosmetic finishes, and are used for cosmetic parts. Producing cosmetic parts requires additional measures to minimize defects such as hang marks and scratches from tools.

Non-cosmetic

Primary machining marks will still be visible

- As machined

- Smooth machining

- Fine machining

- Chromate Conversion Coating

- Electroless Nickel Plating

- Anodized type III (Hardcoat)

- Powder coating

- Black oxide

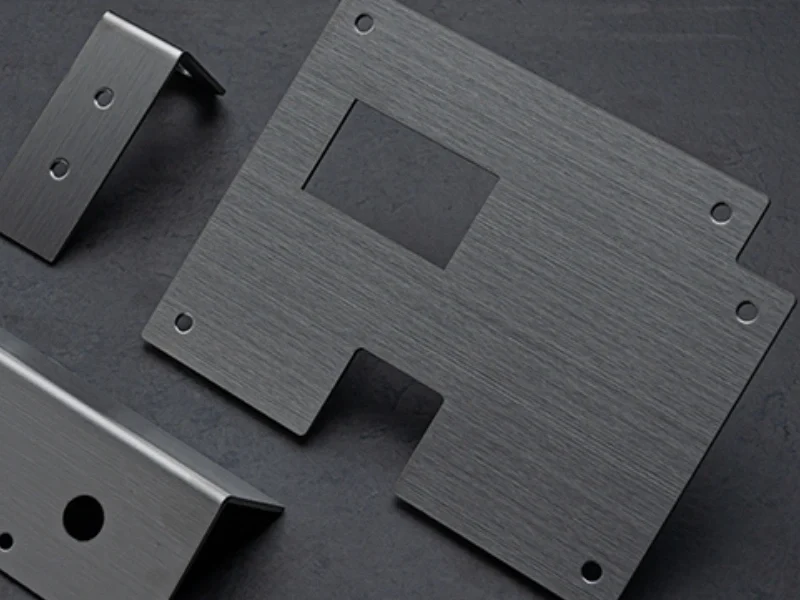

2-rd6ajjt7274ksu8kn08khwd53nrzhbpleohl8hxcog.png)

Cosmetic on request

Finishes can be either cosmetic or non-cosmetic as per request.

- Brushed + Anodizing type II

- Bead Blasted + Anodizing type II

- Bead Blasted

- Brushed

Cosmetic by default

These finishes will always serve a cosmetic function.

- Brushed + Electropolished

- Polishing

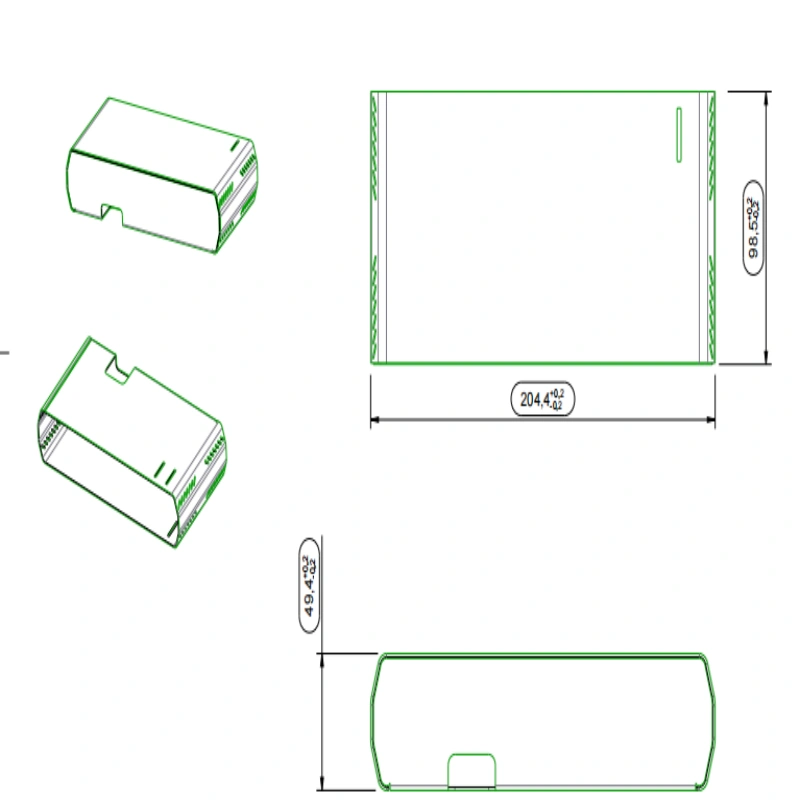

Defining an A and a B side

Surface finishing often leaves aesthetic defects on your parts, such as hang marks for anodizing. Defining an A- and a B-side in your design will ensure that the most important areas of your part remain free of defects.

In this image you can see how you can define an A-side and a B-side in your technical drawing:

A side: Indicates the most aesthetically important surface, typically the visible side of your product.

B side: Indicates the side that is not aesthetically important, typically the side hidden from visibility after assembly.

| Will my part have | Primary surface (A-side) | Secondary surface (B-side) |

|---|---|---|

| Scratches, stains, blemishes | No | No |

| Hanging marks | No | Minor hanging marks |

| Other minor defects | No | Up to 2 minor defects |

For the primary surface (A-side) of your part, we guarantee defect-free production. In contrast, secondary surfaces (B-side) may be machined with hanging marks and other minor defects. B-side surfaces, like the rest of your part, will be free of scratches, stains and blemishes.