Aluminum enclosure – Customizable Aluminum Rackmount Chassis

Designed for industrial applications, this customizable aluminum profile server chassis offers superior heat dissipation, robust protection, and EMC/EMI shielding, all in a lightweight and durable design.

Use Cases

Aluminum profile server chassis are widely used in demanding environments due to their superior performance and flexibility:

- Industrial Automation & Control: They protect industrial PCs, PLCs, and data acquisition equipment in harsh environments like factories and workshops, ensuring stable operation.

- Servers and Data Centers: Ideal as custom chassis for servers and edge computing devices, especially where efficient heat dissipation and lightweight design are crucial.

- Communication Equipment: They house communication base stations, network switches, and routers, providing robust physical protection and thermal management.

- Medical Equipment: They offer reliable enclosure solutions for medical instruments that require high levels of cleanliness and excellent thermal performance.

- Professional Audio/Video Equipment: They provide a durable, aesthetically pleasing, and well-ventilated enclosure for audio amplifiers, mixers, and video servers.

Key Selling Points

- Exceptional Heat Dissipation: The naturally high thermal conductivity of aluminum, combined with the heat-dissipating fin structure created by the extrusion process, allows for rapid heat transfer. This ensures efficient passive cooling, which is vital for high-power, long-running servers and industrial equipment.

- Rugged and Durable: Aluminum is lightweight yet strong and highly corrosion-resistant. The unique extrusion process creates a unified, sturdy structure that can effectively withstand physical impact and vibration, extending the lifespan of internal components.

- Flexible Customization: Aluminum profiles are highly malleable and can be easily customized to meet specific customer needs. This includes various sizes (e.g., 3U, 4U, 5U), precise cutouts, and different surface finishes (e.g., anodizing, sandblasting, brushing) to suit diverse requirements.

Main Advantages

- Lightweight Design: Aluminum’s low density makes the entire chassis significantly lighter than steel alternatives. This simplifies transportation, installation, and maintenance, and is particularly beneficial for applications where weight is a critical factor, such as in aerospace or vehicle-mounted systems.

- EMC/EMI Shielding: Aluminum alloy chassis inherently offer excellent electromagnetic shielding, effectively blocking electromagnetic interference. This protects sensitive internal electronics and ensures the stable operation of the equipment.

- Eco-Friendly and Recyclable: Aluminum is a fully recyclable material, aligning with modern sustainability trends and offering an environmentally conscious solution.

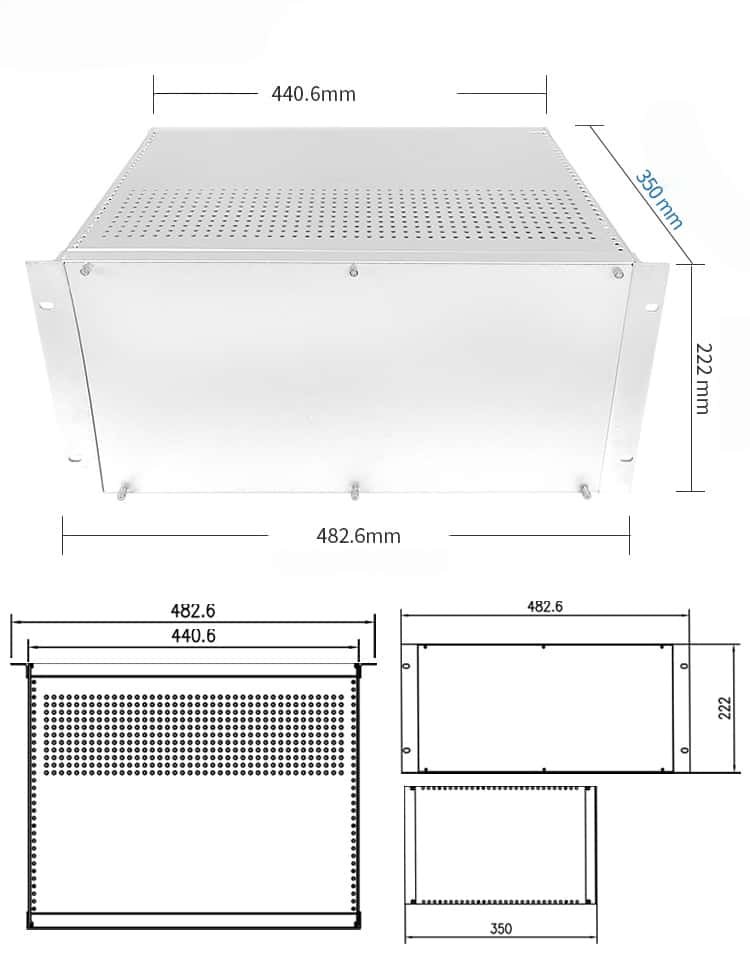

| Specifications | Front Panel: 482.6 x 222 mm |

|---|---|

| Material | 6063 Aluminum |

| Processing technology | surface oxidation treatment process |

| Application scope | Industrial Automation & Control, Servers and Data Centers, Communication Equipment, Medical Equipment, Professional Audio/Video Equipment |

Excellent Extrudability

6063-T5 aluminum is highly favored for its exceptional

Superior Corrosion Resistance

This alloy forms a dense, natural oxide layer that provides outstanding corrosion resistance against atmospheric conditions, water, and many chemicals. This makes it a perfect choice for outdoor or high-moisture environments. The corrosion resistance can be further enhanced with anodizing, which also allows for a variety of colors and finishes.

Application

Applications of Sheet Metal Enclosures

Sheet metal enclosures are primarily used to provide robust and durable protective casings for various electronic, mechanical, and electrical equipment. They play a critical role in numerous industries, including:

Electronics & Telecommunications: Used for casings of servers, networking devices, computers, and telecom base stations.

Industrial Automation: Serve as control cabinets and enclosures for industrial machinery and instruments, providing protection against harsh industrial environments.

Medical Devices: Offer enclosures that meet high standards for cleanliness and safety for diagnostic and monitoring equipment.

New Energy: Applied in devices like PV inverters, charging piles, and energy storage systems to withstand severe outdoor conditions.

Transportation & Security: Protect automotive electronics, railway signaling equipment, and security cameras.

Production and Delivery

Production and Delivery

How long does mold opening take?

15-25 days

How long does sampling take?

Samples are completed in 3-7 days.

How long does mass production take?

15-25 days

Supported Payment Methods

Supported Payment Methods

We support the following payment methods:

Trade Assurance

T/T (Telegraphic Transfer)

VTB (VTB Bank)

Offshore Account

About us

Xiamen Tongcheng Jianhui Industry and Trade Co., Ltd. is a high-tech enterprise specializing in the R&D, production, and sales of diverse electronic and electrical metal enclosures (such as chassis, cabinets, and cases for relays, routers, and industrial control) using a complete set of advanced processing equipment, including CNC punching, bending, and fiber laser cutting machines.

How to Order?

Step One

Send your Files and Request Signed NDA

Step Two

Engineering Analysis Send a Quotation

Step Three

Confirm the Order

Start Manufacturing

Step Four

100 % QC Inspection Machine Part

Step Five

Surface Treatment Feedback to Customer

Step Six

Shipping Feedback Tracking Number

Step Seven

After-sale service

Why Choose us?

With 21 years of experience in the metal parts manufacturing industry, our factory operates with a dedicated team of three professional engineers. We manage the entire production process in-house, from initial mold design and development to final surface treatment. Our comprehensive capabilities include laser cutting, welding, stamping, bending, and CNC machining, all backed by specialized teams, advanced machinery, and extensive expertise.

Comprehensive Metal Fabrication & Machining

We handle the entire production process in-house, from initial mold design and development to final surface treatment. Our comprehensive capabilities, backed by specialized teams, advanced machinery, and extensive experience, include laser cutting, welding, stamping, bending, and CNC machining.

Professional engineering team

We have a professional team of three engineers, all with master’s degrees and over 10 years of experience in mold design and metal manufacturing.

With 21 years of manufacturing experience

With 21 years of experience in the metal parts manufacturing industry, we are a seasoned company specializing in providing high-quality, precision-engineered products to our clients. Over two decades of expertise have allowed us to build a strong foundation of knowledge and exceptional production capabilities, enabling us to meet a wide range of complex design requirements. Our goal is to be a trusted partner for your business, delivering excellence through superior craftsmanship and reliable service.