Custom Metal Enclosure Materials and Surface Treatment Solutions

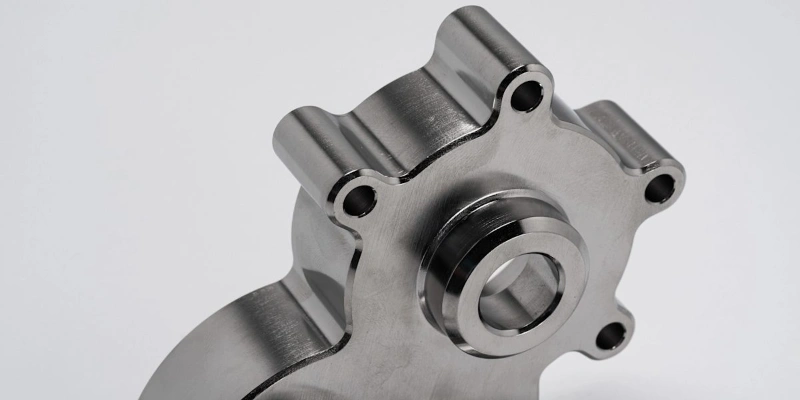

We specialize in manufacturing enclosures using aluminum alloy, iron, stainless steel, and carbon steel. Additionally, we offer an extensive selection of up to 20 different surface treatment options, including brushed finishing, plating, anodizing, and oxidation.

Metal Enclosure Materials

Choose from a wide range of sheet metal materials including aluminum, stainless steel, and brass. Each material is chosen for its unique properties, allowing us to recommend the best match for your project’s specific needs and applications.

METALS

- Aluminium

- Copper

- Bronze

- Steel

- Stainless Steel

- Magnesium

- Titanium

PLASTICS

- ABS

- PC

- PMMA (Acrylic)

Aluminium

Aluminium is lightweight, strong, and easy to machine, positioning it great for various applications like aerospace and automotive parts. Its corrosion resistance also adds to its appeal in outdoor projects and structural components.

Color: Silver

Subtypes: Aluminium 6061, 6061-T6, Aluminium 2024, )

Available Finish: As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

Price: $$

Lead Time: About 5 business days

View More

Copper

Copper provides excellent electrical and thermal conductivity, making it ideal for electronics and heat exchangers. It also offers a visually distinctive appearance and natural antibacterial properties.

Color: Red-Brown

Available Finish: Polishing, Electroplating

Lead Time: About 5 business days

View More

Bronze

Bronze is known for its excellent wear resistance and low friction properties, making it a top choice for bearings, bushings, and marine components.

Color: Brown

Lead Time: About 5 business days

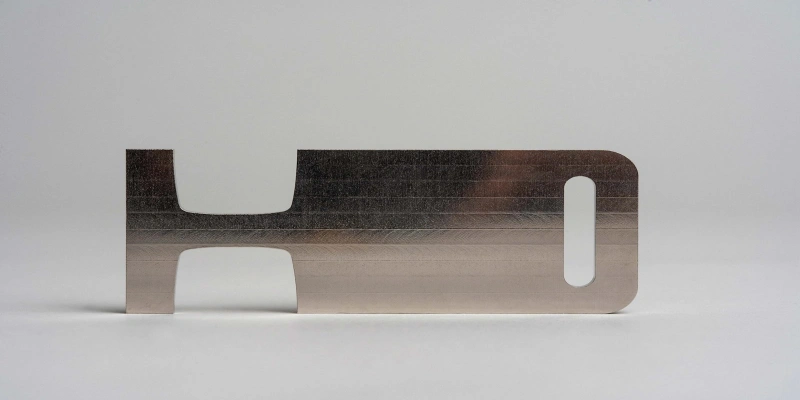

Surface Finishing Options for Metal Enclosures

Improve the durability and appearance of your custom metal parts with our surface finishing options. If you need something different, just choose “Other” and tell us what you’re looking for.

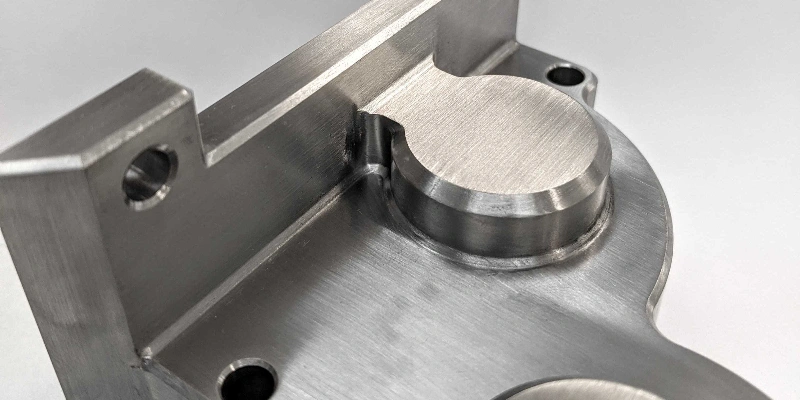

As Machined

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Anodizing

2-rd6ajjt7273fvnjzyuvnfop4byvkxjr87phx6kvelc.png)

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

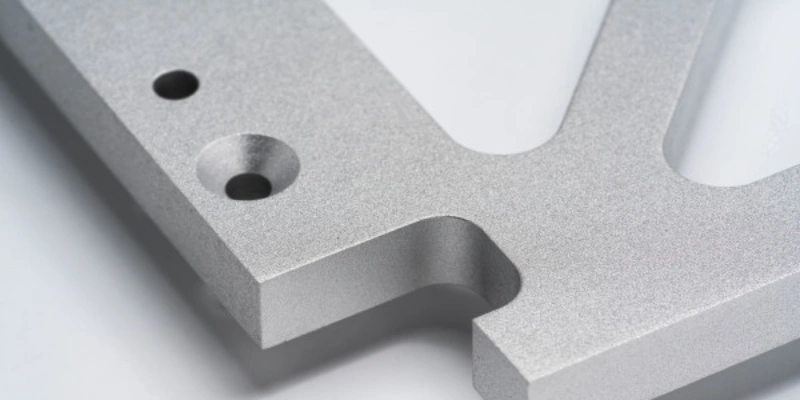

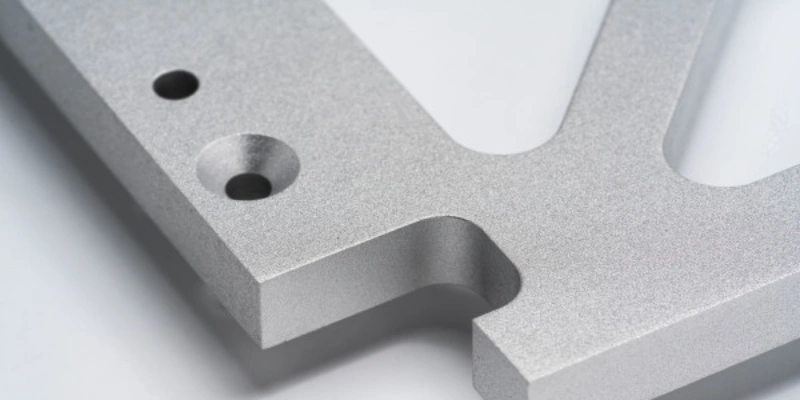

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

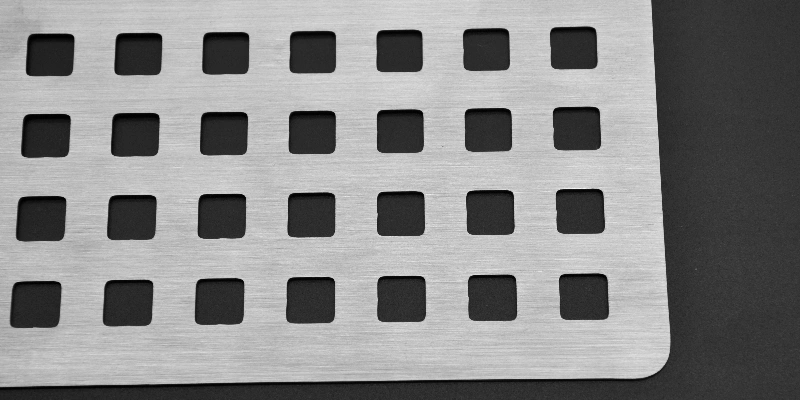

Brushed Finish

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder Coating

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Black Oxidize

Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection.

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.