Custom Sheet Metal Bending Services

Custom metal bending services for high-quality prototypes and production bends. Free sheet metal quote with DFM review within 1 day. Lead time as fast as 3-5 days.

High Quality Parts

Our team of experienced engineers utilizes the latest metal bending technology and rigorous quality control measures to ensure that every bent metal part meets the most exacting standards.

Fast Lead Time

Our CNC bending equipment, coupled with streamlined workflows, allows us to turn around your custom bent parts in record time.

Engineering Support

Our experts guide you through the best choices for your project, from selecting materials to choosing bending methods, making sure you get optimal results every time.

What is Metal Bending?

Metal bending is a fabrication process that involves deforming metal into specific angles or shapes using mechanical force. This process is essential for producing components with precise angles and curves, and due to its ability to create durable and fully functional parts, it has become an indispensable production step across various industries.

At Tongcheng Jianhui, our sheet metal bending services cater to a wide range of customer needs, from simple to complex designs. Equipped with advanced electric and hydraulic press brakes, we ensure high-precision bending, even for parts with tight tolerance requirements.

Our services extend beyond bending alone, as we also offer comprehensive post-processing options. This ensures that the parts you receive are not only accurately bent but also ready for immediate use in either prototype products or final finished goods.

How does Metal Bending Work?

Metal bending is a fundamental process in metal fabrication that involves applying external force (typically with a press brake or similar equipment) to form sheet metal along a straight axis into desired shapes. This technique can accurately process sheet metal into structures such as V-shapes, U-shapes, or channels. The bending methods vary from manual operations to advanced Computer Numerical Control (CNC) technology, with the latter offering superior precision and repeatability.

This metal bending manufacturing technique is widely used due to its ability to efficiently produce structurally robust and fully functional parts. Its applications range from small components like brackets to large architectural features. With advancements in CNC technology, achieving complex and high-precision bending has become more accessible, significantly expanding design flexibility and shortening production cycles. Notably, CNC systems enable mass production with minimal deviation, ensuring high consistency in quality across large batches.

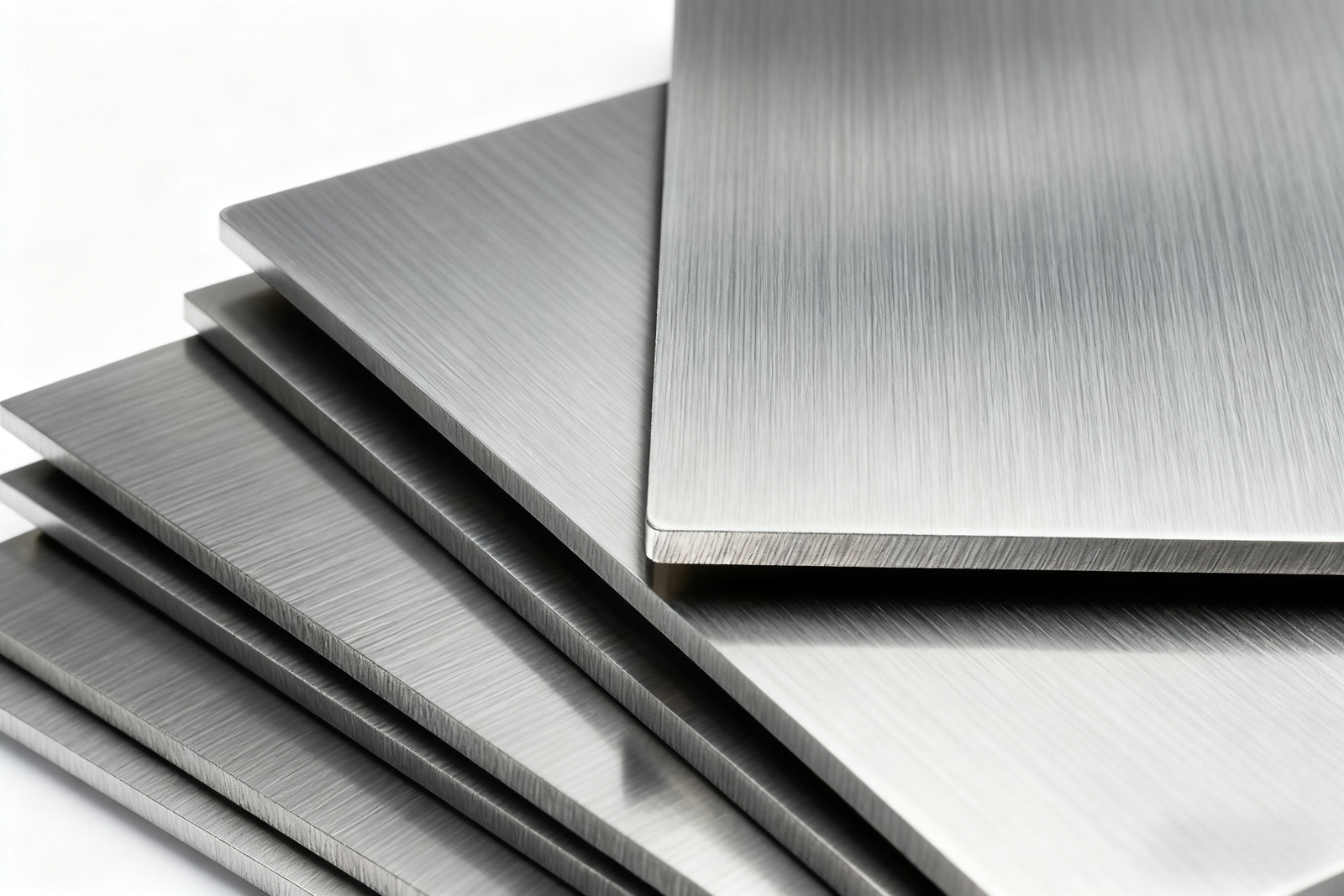

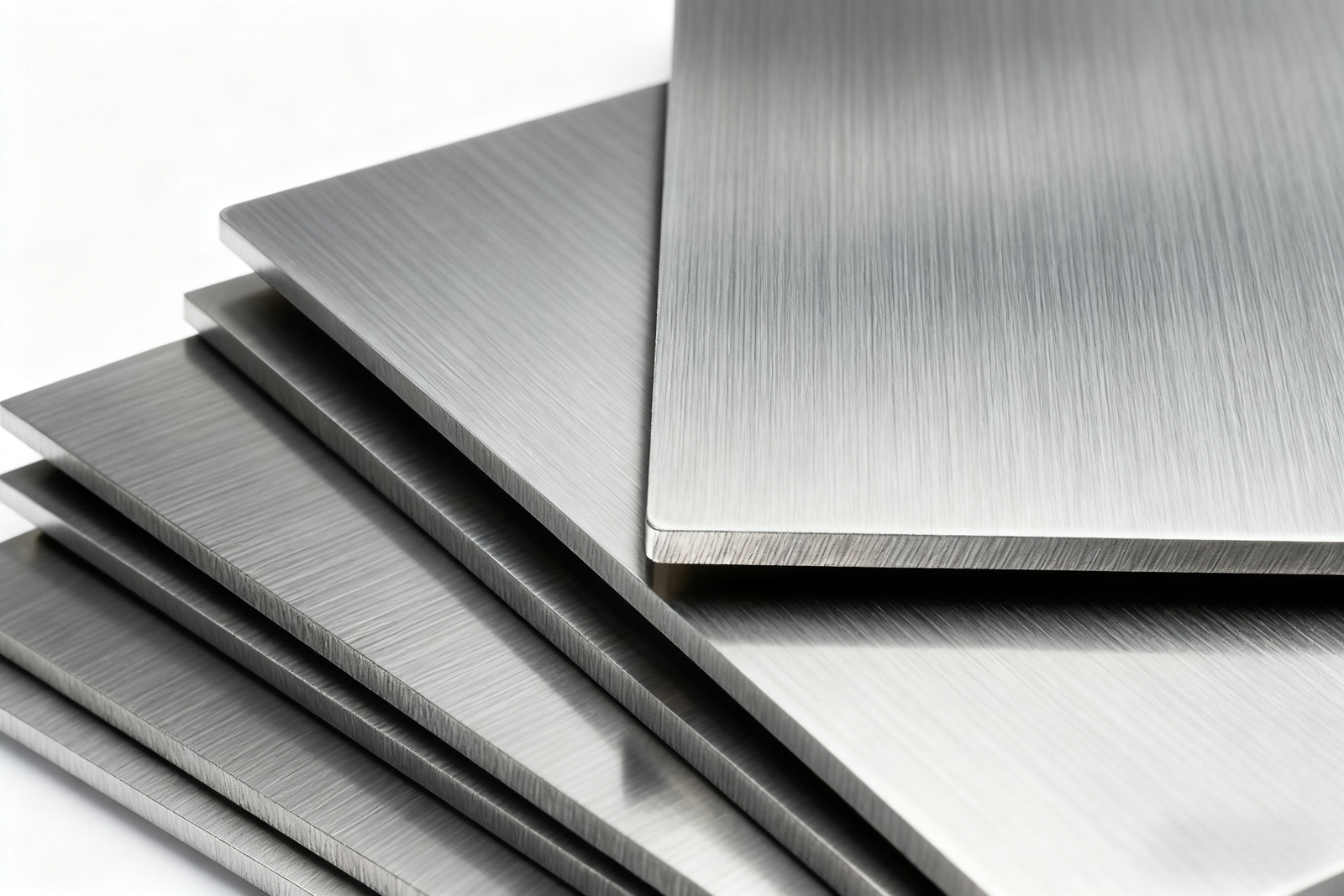

Metal Bending Materials

Choose from a wide range of sheet metal materials including aluminum, stainless steel, and brass. Each material is chosen for its unique properties, allowing us to recommend the best match for your project’s specific needs and applications.

- Aluminium

- Stainless Steeel

Aluminium

Aluminium is lightweight, strong, and easy to machine, positioning it great for various applications like aerospace and automotive parts. Its corrosion resistance also adds to its appeal in outdoor projects and structural components.

Color: Silver

Subtypes: Aluminium 6061, 6061-T6, Aluminium 2024, )

Available Finish: As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

Price: $$

Lead Time: About 5 business days

View More

stainless

Stainless steel offers exceptional corrosion resistance and high strength, making it ideal for kitchenware and architectural applications. It also provides a sleek, modern appearance and hygienic, easy-to-clean properties.

Color: White

Available Finish: Polishing, Electroplating

Lead Time: About 5 business days

Metal Bending Capabilities

| Description | |

|---|---|

| Maximum Part Size | 1.5 m x 1.5m |

| Metal Bending Forces | Up to 1000 tons |

| Bending Line Length | Up to 7200 mm |

| Bending Thickness | Up to 60 mm |

| General Tolerances | Our metal bending standards depend on ISO 2768. |

| Bend to edge/hole, single surface | +/- 0.254 mm (+/- 0.010 in.) |

| Bend Radius | Be equal to material thickness |

| Bend Angle | +/- 1° |

| Bend Cutting Area | Up to 4000 mm |

| Lead Time | 5 days or more |

Tongcheng Jianhui Metal Bending Workshop

Advantages of Bending Manufacturing

Metal bending manufacturing is integral across multiple sectors due to its distinct advantages:

Cost Efficiency

Reduces part count, welding, and assembly, lowering overall costs.

Enhanced Strength

Increases durability at bends, allowing lighter designs without sacrificing strength.

Precision & Flexibility

CNC technology ensures high accuracy and repeatability for diverse metals and applications.

Aesthetic Improvement

Creates clean, attractive lines for visually critical components.

Applications of Bent Metal Parts

Bent metal parts serve a multitude of purposes, transforming sheets into durable, functional components with a wide range of applications:

Enclosures and Casings

Custom bent enclosures house everything from electronics to industrial machinery, offering protection and support while maintaining accessibility and aesthetics.

What’s the bending process?

- Metal Bending Process

- Fundamental Definition: A fundamental metalworking process that involves deforming a sheet metal blank along a straight axis by applying force, typically using a press brake, to create desired shapes like V-bends, U-channels, or other profiles.

- Basic Process: The sheet metal is positioned between a punch and a die. The punch then forces the metal into the die cavity, causing it to bend and take the shape of the die.

- Key Parameters: Critical parameters controlled during the process include the bend angle, bend radius, and bending force, which collectively determine the final geometry of the part.

- Technology: The methods range from manual operations to advanced Computer Numerical Control (CNC) systems. CNC technology offers superior **precision, repeatability**, and the ability to perform complex bending sequences.

- Key Advantages:

Efficient production of strong, functional parts.

Offers great design flexibility.

Enables faster production cycles. - Applications: Extremely versatile, used to manufacture everything from small components (e.g., brackets) to large architectural elements.

What is the tolerance of bent parts?

The tolerance of bent parts refers to the acceptable deviation from the specified dimensions that can occur during the bending process. These tolerances are critical in ensuring that the parts fit properly in their intended assembly and perform their function as expected.

For standard sheet metal bending, tolerances typically range from ±0.1 mm to ±0.5 mm. However, the specific tolerances can vary based on several factors including the type of metal, the thickness of the sheet, and the complexity of the part design. Thinner metals may exhibit greater variability due to their increased flexibility and susceptibility to springback—a phenomenon where the metal tries to return to its original shape after bending.

Advanced CNC bending machines can achieve very precise tolerances by precisely controlling the angle and position of the bend. For critical applications requiring extremely high precision, such as in aerospace or medical devices, tolerances might be even tighter, often within the range of ±0.01 mm to ±0.1 mm.

RapidDirect will carefully consider the bending method and tooling to match the required tolerances for the application, ensuring optimal performance and fit of the bent parts.

Are die marks visible on bent metal parts?

Key Points on Die Marks:

Issue: Indentations or scratches from the bending process that affect aesthetics and strength.

Factors: Material softness, tool condition, and processing methods.

Solutions: Use of protective films/cushioning pads for prevention; grinding/polishing for elimination.

Is there a maximum thickness for the sheet metal that can be bent?

Yes, there is a maximum thickness for sheet metal that can be bent, which largely depends on the type of bending machine used and the material properties of the metal. Generally, the capacity to bend metal sheets is determined by the tonnage of the press brake and the length of the bend. Higher tonnage machines can handle thicker materials, but there are practical limits based on the metal’s type and the desired bend angle.

For common materials like aluminum and mild steel, many standard press brakes can bend sheets up to about 0.5 inches (12.7 mm) thick. However, for tougher materials like stainless steel, the maximum thickness typically decreases due to the material’s higher tensile strength, which requires more force to bend. For these types of metals, thickness might be limited to around 0.375 inches (9.5 mm).

It’s also important to consider the bend radius; thicker metals require a larger radius to avoid cracking or breaking during the bending process. Manufacturers need to balance machine capabilities, material characteristics, and design requirements to determine the feasible maximum thickness for any given bending project.

Which metal offers the highest resistance to bending?

Among commonly used metals in fabrication, stainless steel typically offers the highest resistance to bending. This resistance is primarily due to its high tensile strength and hardness, which make it more challenging to deform compared to metals like aluminum or mild steel. The composition of stainless steel, which includes significant amounts of chromium and nickel, not only provides excellent corrosion resistance but also contributes to its stiffness and durability.

The high resistance of stainless steel to bending requires more force to shape, often necessitating the use of press brakes with higher tonnage capabilities. Additionally, due to its tough nature, proper tooling and techniques must be employed to prevent damage to the machinery or the workpiece itself, such as cracking or brittleness at the bend.

This characteristic makes stainless steel ideal for applications where structural integrity and durability are paramount, such as in medical devices, food processing equipment, and marine applications. However, the increased difficulty in bending can also lead to higher manufacturing costs and more complex processing requirements.

What is the bend rule for sheet metal?

What are the types of sheet metal bending?

What is the easiest sheet metal to bend?

Aluminum is frequently considered the easiest sheet metal to bend due to its softness and ductility, which allows for more straightforward manipulation. Thin gauges of aluminum can be bent with minimal effort, making it ideal for various applications, including fabrication and prototyping. Additionally, aluminum’s resistance to cracking during bending enhances its workability, making it a popular choice among manufacturers and DIY enthusiasts alike.

Can I request custom bend angles for my sheet metal parts?

How do you ensure the quality of the bent parts?

RapidDirect maintains quality by utilizing advanced CNC bending technology, which ensures precision and consistency in every part produced. Our process includes rigorous inspections at multiple stages, checking for accuracy in dimensions and alignment. Additionally, we adhere to strict industry standards, guaranteeing that each bent part is durable and reliable for its intended application.