Reviting & Assembly Services

Backed by 21 years of experience in metal casing manufacturing, we know that the right connection is core to structural strength and lasting performance. We expertly leverage both riveting and welding to provide the optimal solution for your design, guaranteeing a rock-solid casing.

Aluminum Enclosure

For aluminum alloy housings, blind riveting offers an optimal balance of flexibility and a heat-free process, while the welding choice depends on the priority: TIG for quality, laser for efficiency, or friction stir for superior performance.

Stainless Steel

For stainless steel housings, blind riveting is the preferred mechanical method, while welding options are chosen by priority: TIG for maximum quality, laser for precision, or spot welding for high-volume production.

Carbon Steel

For carbon steel, solid rivets provide maximum strength for heavy structures, while blind rivets offer quick, one-sided fastening for lighter assemblies. For welding, MAG is the most efficient all-purpose process, Stick welding is the most portable and economical, and TIG welding delivers the highest quality finish for critical applications.

Riveting Services

With 21 years of manufacturing experience, we possess extensive expertise in various casing-related riveting processes, enabling us to provide optimal connection solutions tailored to your specific product requirements.

Blind riveting

Blind riveting is paramount for metal enclosures due to its unique capability for one-sided installation, which offers a convenient, cost-effective, and reliable fastening solution.

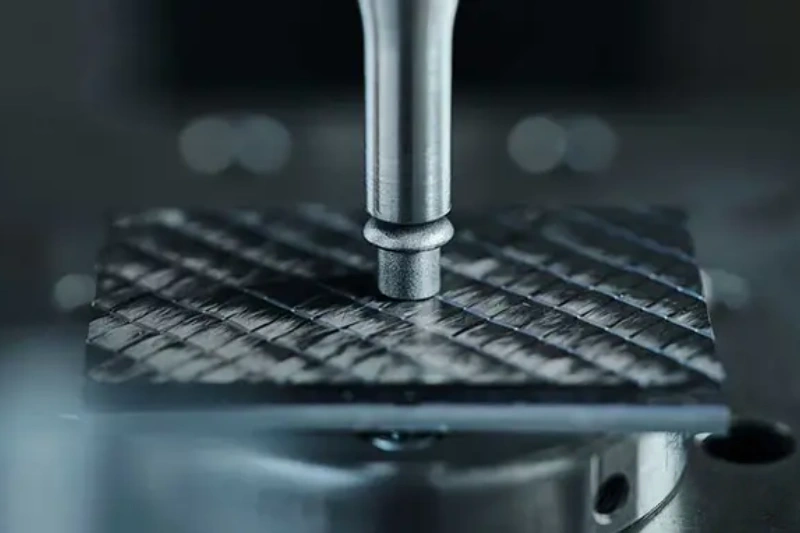

Self-piercing riveting

Self-piercing riveting (SPR) is ideal for joining steel and aluminum sheets (typically 0.5-3mm total thickness), creating high-strength bonds between dissimilar materials. Its key advantages are the elimination of pre-drilled holes, no heat-induced distortion, and high production efficiency.

Clinching

Clinching is ideally suited for thin sheets (0.5mm~3.0mm) of ductile materials like aluminum, mild steel, and copper. Its core advantages lie in exceptional efficiency, very low cost per joint, excellent sealing capability, and its nature as a green, environmentally friendly process.

Welding Methods for Parts

Our dual quality system—strict compliance with ISO 5817 and hourly IPQC checks—provides real-time oversight, assuring the delivery of superior, zero-defect welding.

TIG Welding

Our TIG welding is capable of maintaining weld width within a standard tolerance of ±0.5mm or a tight tolerance of ±0.2mm for high-precision applications.

MAG/MIG welding

We are capable of holding laser welding tolerances to ±0.2mm as standard, with high-precision capabilities down to ±0.1mm.

Laser Welding

We are capable of holding laser welding tolerances to ±0.2mm as standard, with high-precision capabilities down to ±0.1mm.