Comprehensive Guide to Metal Enclosure Fabrication: Processes, Materials & Quality Control

Yang Tianming

Principal Engineer | 21 Years in Sheet Metal Fabrication

My expertise lies in die/mold design and manufacturing and sheet metal process optimization. I focus on technical problem-solving from the tooling source to mass production, driving cost efficiency and quality assurance.

In today’s industrial and electronics sectors, metal enclosure fabrication plays a crucial role. As a specialized metal enclosure manufacturer focusing on mass production of metal enclosures, we understand how high-quality, customized metal enclosures impact the performance and safety of our customers’ products. This article explores the core processes and technologies involved in custom metal enclosure fabrication and sheet metal enclosure fabrication from a manufacturer’s perspective, helping bulk procurement companies better understand the key factors for selecting a reliable supplier.

Table of Contents

1. What is Metal Enclosure Fabrication?

Metal enclosure fabrication refers to the process of creating protective metal housings designed to safeguard electronic devices, industrial machinery, or other critical components. These enclosures provide physical protection while also resisting environmental corrosion and mechanical stresses to ensure stable operation. Common materials include stainless steel, aluminum, and carbon steel—each offering unique benefits and suited for different applications.

2. Manufacturer’s Perspective on Custom Metal Enclosure Fabrication

Bulk purchasing clients often require personalized enclosures that meet specific functional needs. As manufacturers, we start by fully understanding client design requirements, usually working from CAD drawings or assisting in creating custom designs. This ensures each production batch meets functional, dimensional, and quality standards while optimizing manufacturing efficiency and cost control.

Producing custom enclosures requires balancing flexibility with scalability. We use advanced machinery and standardized processes to ensure product consistency and timely delivery. Our strict quality management system inspires customer confidence.

3. Key Processes in Sheet Metal Enclosure Fabrication

Metal enclosure fabrication relies on several core process steps. Below, we provide detailed technical insights into each phase and the materials best suited.

3.1 Sheet Metal Cutting Technology

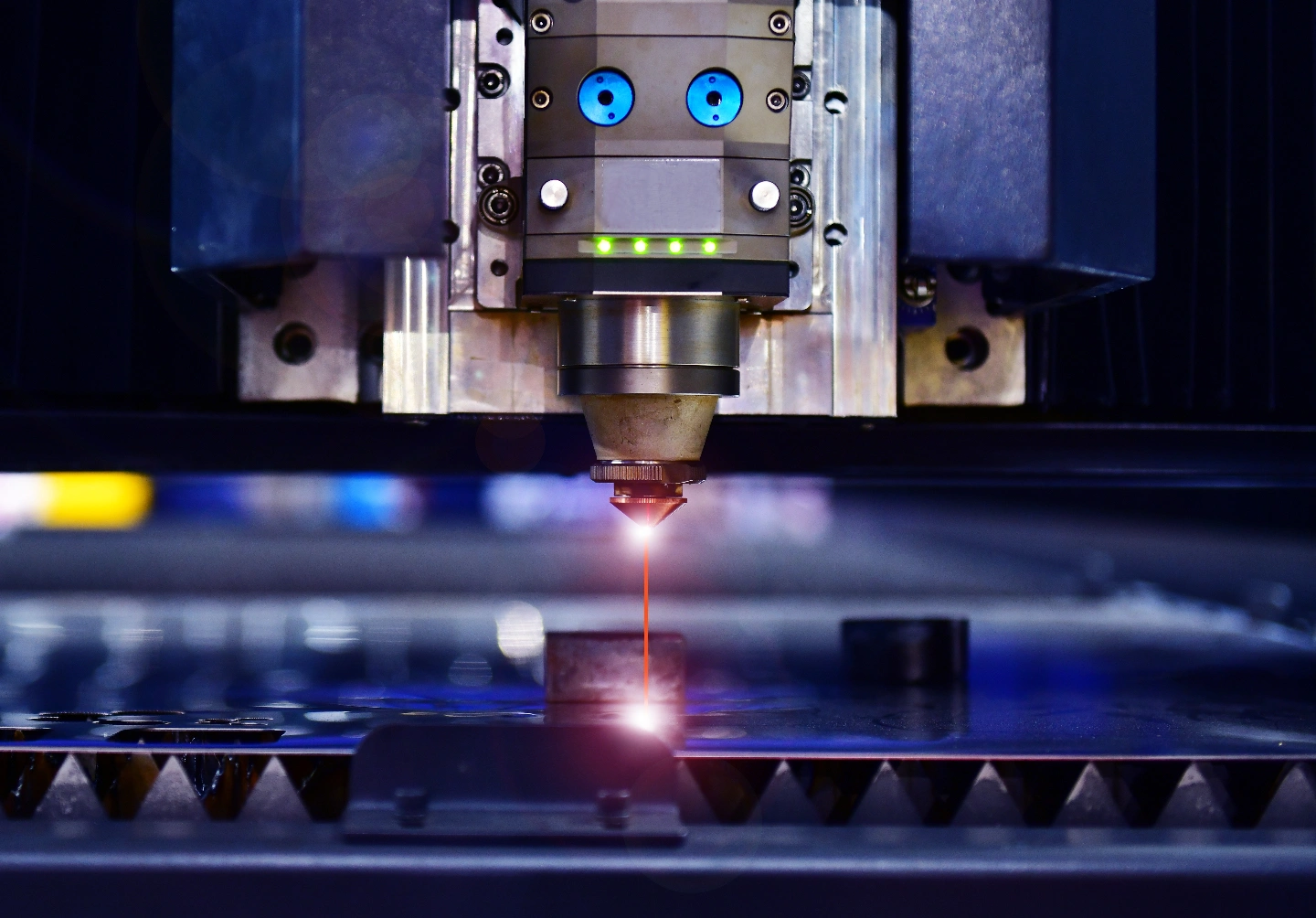

Types of Laser Cutting

Laser cutting is widely applied in sheet metal fabrication and generally falls into several categories:- CO2 Laser Cutting: Uses CO2 gas as laser medium, suitable for cutting non-metal materials and thin metal sheets. It produces smooth cut edges with stable energy output.

- Fiber Laser Cutting: Utilizes fiber optics for laser transmission, delivers highly concentrated energy, extremely efficient especially for metals like stainless steel, aluminum, and copper with lower maintenance costs.

- Solid-State Laser Cutting (e.g., Nd:YAG): Used in high-precision or microfabrication work but less common in mass sheet metal cutting.

Materials Suitable for Laser Cutting and Reasons

Laser cutting works best on thin metal sheets between 0.1mm and 20mm thickness, commonly including:- Stainless steel (models such as 304, 316)—balanced hardness and good laser absorption.

- Aluminum alloys (6061, 5052)—higher thermal conductivity but manageable with fiber lasers.

- Carbon steel (Q235, SPCC)—cost effective for large volume cutting.

The choice favors high precision and minimal heat-affected zones, often eliminating the need for secondary processing.

Materials and Grades Suitable for Stamping and Reasons

Stamping is suitable for rapid and mass forming with materials exhibiting excellent plasticity and ductility:- Low carbon steel (SPCC, DC01)—cost effective with good formability.

- Stainless steel (type 304 with good toughness)—resistant to corrosion, suitable for complex shapes but requires higher tooling standards.

- Aluminum alloys (1050, 1100)—extremely formable and lightweight for stamping.

Material selection focuses on ductility and uniform thickness to avoid cracking or defects under high press forces.

3.2 Bending and Forming Processes

Materials Suitable for Bending

- Low carbon steel (SPCC, Q235): excellent ductility and low cost, ideal for standard bending operations.

- Stainless steel (304, 316): corrosion-resistant with sufficient ductility, suitable for structural integrity.

- Aluminum alloys (6061, 5052): lightweight and easy to bend, preferred for weight-sensitive applications.

Materials Suitable for Extrusion and Reasons

Extrusion forms long profiles with complex cross-sections, dominant in aluminum alloys:- Aluminum 6063 and 6061 alloys have excellent plasticity and strength, perfect for hot extrusion processes.

- While low carbon steels can be cold-extruded, aluminum extrusions are more common in industry.

These materials combine good formability with economic viability in continuous profile shapes.

3.3 Welding and Assembly Processes

Types of Welding with Pros and Cons

- TIG Welding (Tungsten Inert Gas): Produces high-quality, aesthetically pleasing welds and is suitable for thin metals but slower and with higher equipment costs.

- MIG Welding (Metal Inert Gas): Offers fast welding speeds ideal for bulk production with good penetration; however, requires clean welding surfaces.

- Spot Welding: Effective for thin sheet joining with strong weld spots and high automation but limited to small localized welds unsuited for thicker parts.

Materials Suitable for Welding

Stainless steel (304/316), low carbon steels (SPCC/Q235), and certain aluminum alloys can be welded using these methods.Riveting Techniques and Differences

- Mechanical Riveting: Traditional method using rivets for mechanical interlocking; simple but generally provides permanent joints.

- Blind Riveting (Pull Rivets): Uses specialized tools to pull rivet shafts forming tight joints, ideal for multi-material or thin sheet connections.

- Structural Blind Rivets (Cherry/Pop Rivets): Have retractable cores creating high strength fastenings, suitable for joining dissimilar materials or difficult weld spots.

Welding fuses metals at the molecular level for permanent bonds. Riveting uses mechanical deformation to fasten parts. The choice depends on joint strength, disassembly needs, and substrate compatibility.

3.4 Surface Treatment Adapted to Different Materials

Material Surface Treatments Comparison

| Material | Suitable Surface Treatments | Advantages | Disadvantages | Principle Summary |

|---|---|---|---|---|

| Stainless Steel |

|

|

| Modify surface texture or apply protective/decorative layer via physical/chemical means |

| Aluminum Alloy |

|

|

| Electrochemical oxidation forms dense aluminum oxide film; powder coating forms uniformly adhered polymer layer after curing |

| Carbon Steel |

|

|

| Phosphating chemically creates protective layers; powder coating cures to durable surface |

Comparison of surface treatment methods for common engineering materials

3.5 Quality Inspection Methods

Maintaining quality in mass production is critical, commonly performed by:

- Dimensional Inspection: Using Coordinate Measuring Machines (CMM), laser measurement tools, and calipers to assure dimensional accuracy within tolerances.

- Weld Inspection: Using nondestructive testing such as ultrasonic or X-ray techniques to locate internal weld defects.

- Surface Inspection: Visual and microscopic examination of coating uniformity and defects such as bubbles or cracks.

- Mechanical Tests: Bending and impact testing to confirm material and weld strength.

- Corrosion Resistance Tests: Salt spray testing to evaluate surface treatment effectiveness for outdoor durability.

4. Suitable Sheet Metal Materials and Their Impact

As professional metal enclosure manufacturers, we operate modern large-scale automated lines — for example, Dalsin Industries utilizing fully automated Salvagnini S4+P4 equipment — dramatically improving efficiency and product consistency. Fast prototyping and responsive support ensure customized requirements are quickly realized.

We emphasize cost control without compromising quality. Comprehensive after-sales support and technical consulting help clients overcome design and manufacturing challenges, achieving long-term partnership success.

6. Industry Application Cases

- Telecommunications: Producing large volumes of NEMA-rated telecom equipment enclosures that guarantee operational safety.

- Energy Sector: Manufacturing specialized metal enclosures for renewable energy applications like wind and solar.

- Industrial Machinery and Outdoor Equipment: Durable, reliable protective housings engineered for harsh, industrial environments.

These examples demonstrate our manufacturing prowess across diverse, demanding fields.

7. Conclusion: Key Points for Choosing a Quality Metal Enclosure Manufacturer

When selecting a manufacturer for bulk procurement, consider:

- Extensive experience and technical capabilities assuring product quality.

- Flexible and efficient customization capabilities to meet various order requirements.

- Stable volume supply capacity with reliable delivery schedules.

- Continuous innovation in design and manufacturing to enhance product value.

Picking the right partner directly influences project success.

If you are looking for a trusted metal enclosure fabrication supplier, please contact us for professional customized solutions and competitive bulk pricing. We offer free design consultation and rapid prototyping to help you gain an edge in the market.