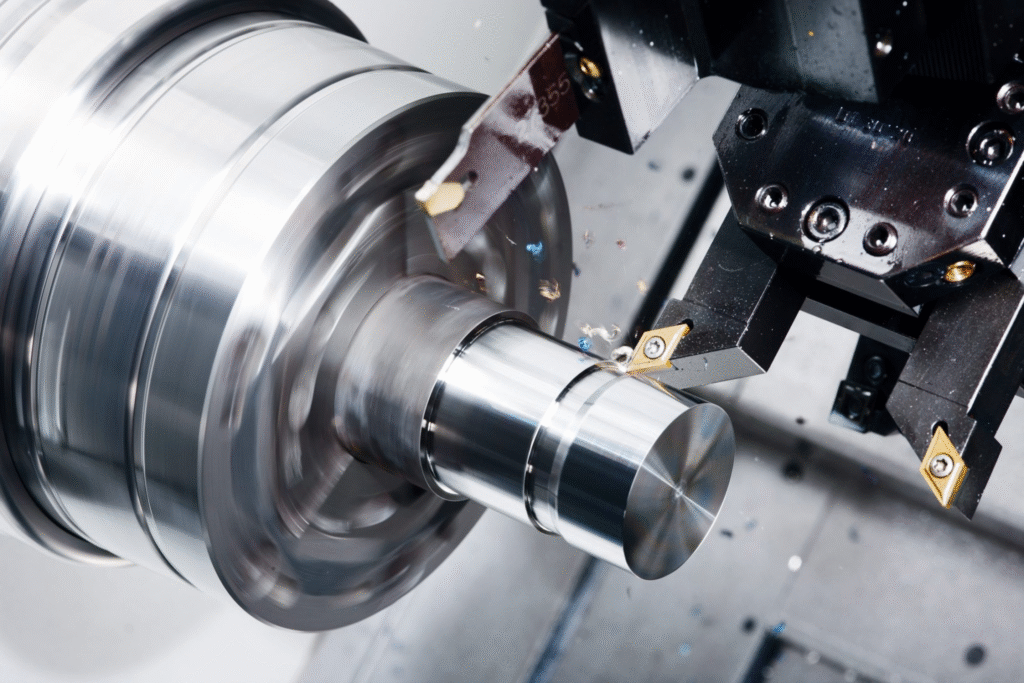

Custom Online CNC Turning Services

Custom CNC turning services with fast lead times and competitive pricing from rapid prototyping to production runs. 0.005 mm tight tolerance. Lead time as fast as 1 day.

CNC Turning With Tongchengjianhui

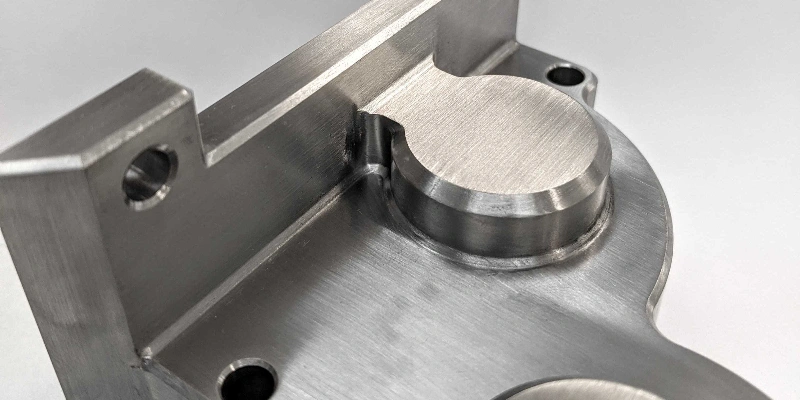

Take advantage of the on-demand CNC turning service and get reliable metal and plastic turned parts for your unique projects. With advanced technologies and expert technicians, RapidDirect produces high-quality custom prototypes and end-use production parts. Our CNC turning capabilities allow us to deliver turned parts with high accuracy, regardless of the complexity. You will get durable parts from flats to radial and axial holes, slots, and grooves as fast as one day.

Our precision CNC turning lathes provide low-cost parts for simple and complex cylindrical geometries. We also use Live tooling to create precise, complex geometries for features like axial and radial holes, grooves, slots, and flats. Full automation of these versatile machines allows us to produce hundreds of similar dimensions easier, faster, and cost-effectively.

CNC Turning Solutions

orem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Rapid Prototyping

Accelerate product development with our rapid machining services. We offer fast turnaround times and specialize in quick production of high-quality prototypes and mold tooling, aiding your design verification process.

Low and High-Volume Production

Whether you need small batches or large-scale production, we can offer you both. With stringent tolerance controls and comprehensive capabilities, we adapt to your volume requirements without compromising on quality.

CNC Turning Materials

Our CNC turning processes work with a diverse array of materials, including machine-grade metals and plastics. Whether you need precision turning of aluminum parts or other materials, we can produce accurate rapid prototypes and low-volume production runs to meet your needs. Check out some of the common materials for your CNC turning projects.

- Aluminium

- Steel

- Stainless Steel

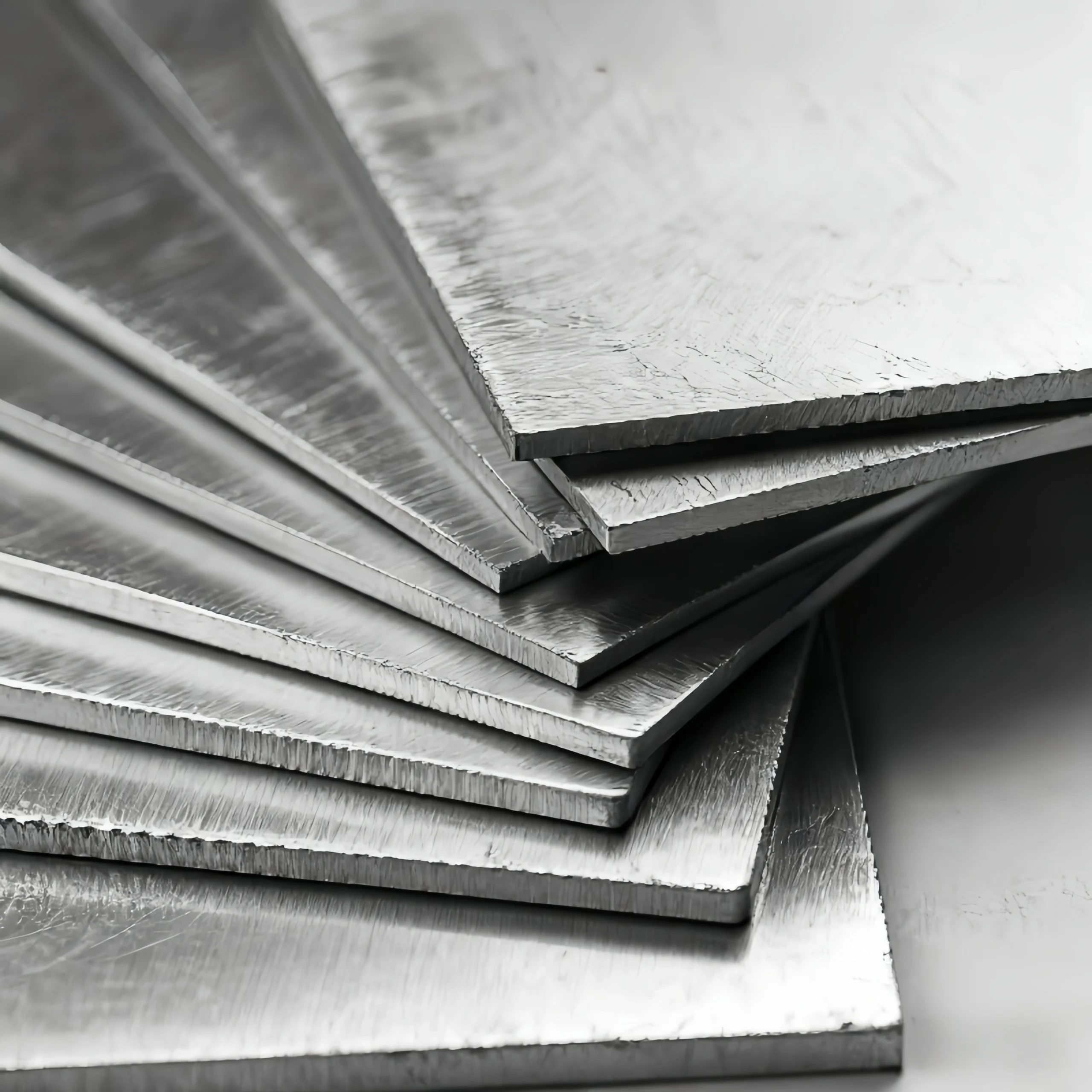

Aluminium

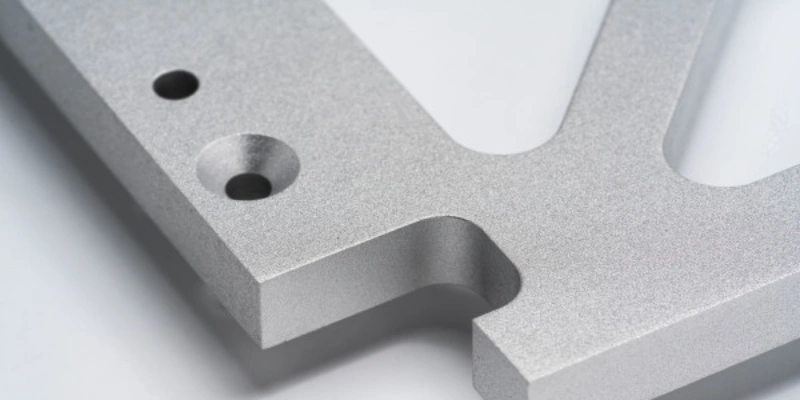

Aluminium is lightweight, strong, and easy to machine, positioning it great for various applications like aerospace and automotive parts. Its corrosion resistance also adds to its appeal in outdoor projects and structural components.

Color: Silver

Subtypes: Aluminium 6061, 6061-T6, Aluminium 2024

Available Finish: As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

Price: $$

Lead Time: About 5 business days

View More

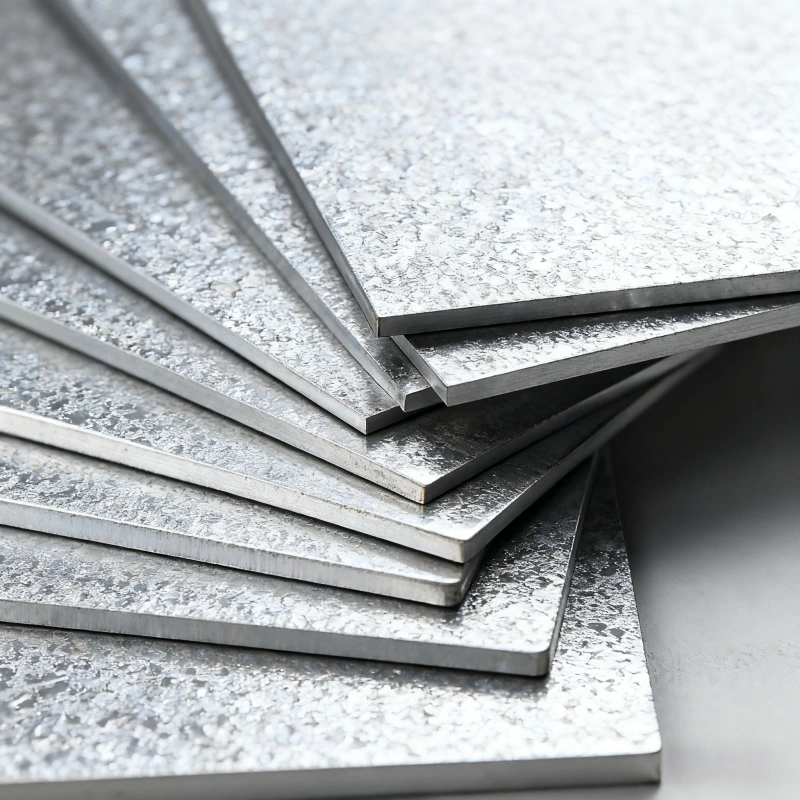

Steel

Steel is an alloy of iron and carbon, known for its high tensile strength and durability. It's widely used in construction, manufacturing, and automotive industries due to its versatility and cost-effectiveness.

Color: Dark Gray

Subtypes: Carbon Steel, Alloy Steel, Tool Steel

Available Finish: As rolled, Galvanized, Painted, Powder coated, Polished

Price: $

Lead Time: About 3-5 business days

View More

Stainless Steel

Stainless steel is an alloy of iron, chromium, and other elements, prized for its corrosion resistance and sleek appearance. It's commonly used in kitchenware, medical equipment, and architectural applications.

Color: Silver

Subtypes: 304, 316, 430, 17-4 PH

Available Finish: Brushed, Mirror, Satin, Bead blasted, Anodized

Price: $$$

Lead Time: About 5-7 business days

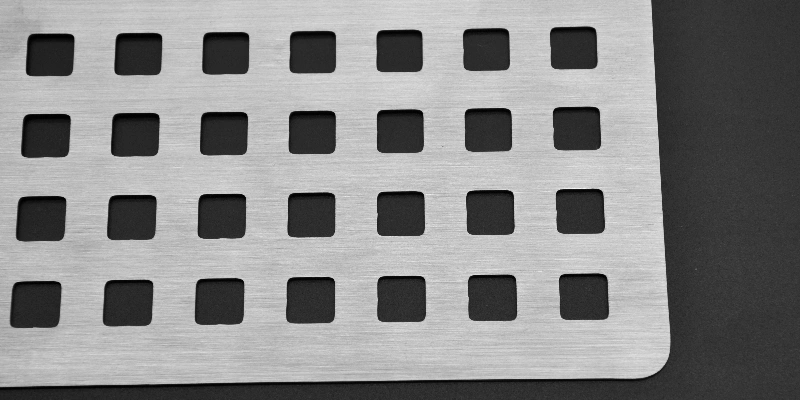

View MoreCNC Turning Surface Finishes

With a wide selection of surface finishes, RapiDirect can help improve the surface qualities of your products. Surface finishes applied to your CNC turned parts aim at improving their appearance, surface hardness and roughness, chemical and corrosion resistance, etc. They also help hide any visible tool marks from areas cut with live tooling. Here are some of your top choices.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

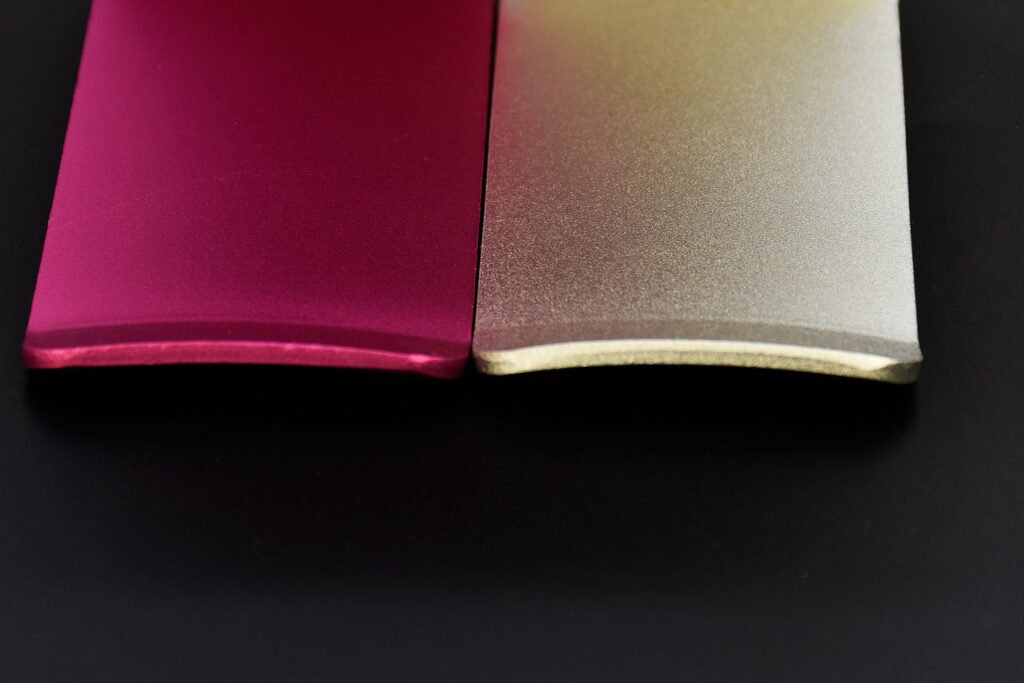

Anodizing

2-1024x685.png)

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Black Oxidize

Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection.

Brushed Finish

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder Coating

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Tolerances for CNC Turning

As an ISO 9001 certified company, we machine CNC turning lathe parts to meet tight tolerance requirements. Based on your design, our CNC lattes can reach tolerances of up to ±0.005”. Our standard tolerances for CNC milled metals is ISO 2768-m and ISO 2768-c for plastics.