| Name | Service | Applicable to | Machining marks | Cosmetic availability | Tolerances |

|---|---|---|---|---|---|

| As machined |

CNC machining,

Sheet metal fabricat ion |

Metals, Plastics | Visible, light surface scratches | No | Met after coating |

| Sand Blasting | CNC machining, Sheet metal fabrication | Metals | Removed on primary surfaces | Always cosmetic | Met after coating |

| Brushing | CNC machining, Sheet metal fabrication | Metals | Reduced for non-cosmetic, removed on primary surfaces for cosmetic | On request | Met after brushing |

Note: The table data represents standard industry parameters and is subject to actual machining requirements and equipment accuracy.

Basic Surface Finishes

The core purpose of basic surface finishing is functional preparation and cost control, rather than achieving aesthetic appeal. It serves as a foundational step in the manufacturing process and is essential for ensuring high-quality subsequent treatments.

As Machined

As-machined condition refers to the raw state of a part without any additional surface treatment

- Visible tool marks

- Moderate to high surface roughness

- Possible presence of small burrs or sharp edges

- Lack of uniform visual appearance

- Functionality prioritized over aesthetics

Sand Blasting

It removes contaminants and creates a uniform micro-rough surface, essential before painting, powder coating, or electroplating.

- Clean the surface

- Increase surface roughness (anchor profile)

- Improve appearance

- Deburr and radius edges

- Induce compressive stress (under specific conditions)

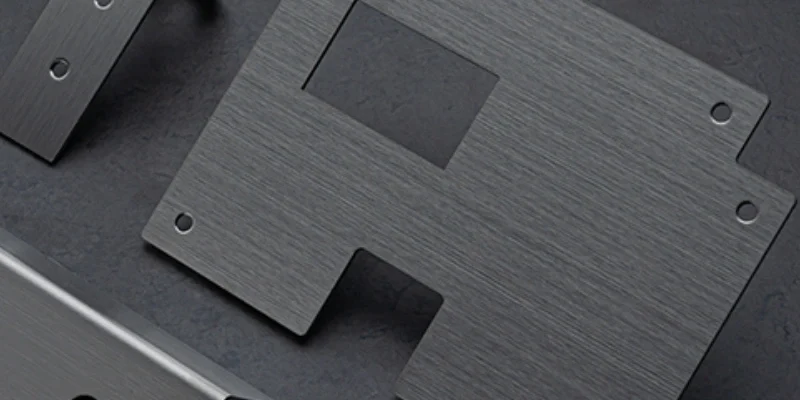

Brushing

Brushing enhances metal’s look with controlled scratches, giving a “subtle luxury” finish—ideal for premium visible parts.

- Not a high-precision functional treatment

- Conceals minor scratches

- Matte or semi-gloss appearance

- Directional linear grain

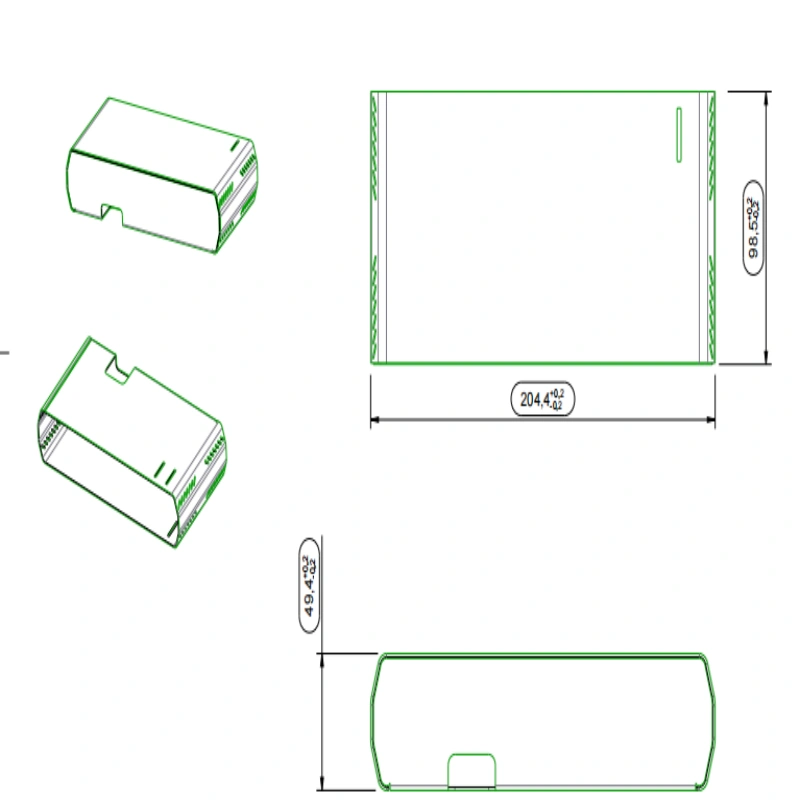

Defining an A and a B side

Surface finishing often leaves aesthetic defects on your parts, such as hang marks for anodizing. Defining an A- and a B-side in your design will ensure that the most important areas of your part remain free of defects.

In this image you can see how you can define an A-side and a B-side in your technical drawing:

A side: Indicates the most aesthetically important surface, typically the visible side of your product.

B side: Indicates the side that is not aesthetically important, typically the side hidden from visibility after assembly.

For the primary surface (A-side) of your part, we guarantee defect-free production. In contrast, secondary surfaces (B-side) may be machined with hanging marks and other minor defects. B-side surfaces, like the rest of your part, will be free of scratches, stains and blemishes.

| Will my part have | Primary surface (A-side) | Secondary surface (B-side) |

|---|---|---|

| Scratches, stains, blemishes | No | No |

| Hanging marks | No | Minor hanging marks |

| Other minor defects | No | Up to 2 minor defects |