What is Metal Parts Stamping? The Fundamental Process Explained

For years, I’ve had my hands in the world of manufacturing, and if there’s one process that I’ve seen as the silent workhorse behind so many products we use daily, it’s metal parts stamping. It’s one of those things you don’t really think about, but once you start to see it, you’ll realize it’s everywhere—from the components in your car to the casing of your phone and even the pots and pans in your kitchen.

So, what exactly is it? At its heart, metal stamping is a manufacturing process that uses a punch press and a specialized stamping die to transform flat sheets of metal into specific shapes. Think of it like a giant, industrial-scale cookie cutter. You take a flat sheet of metal, place it on the die, and the press comes down with immense force, cutting and forming the metal into the desired shape.

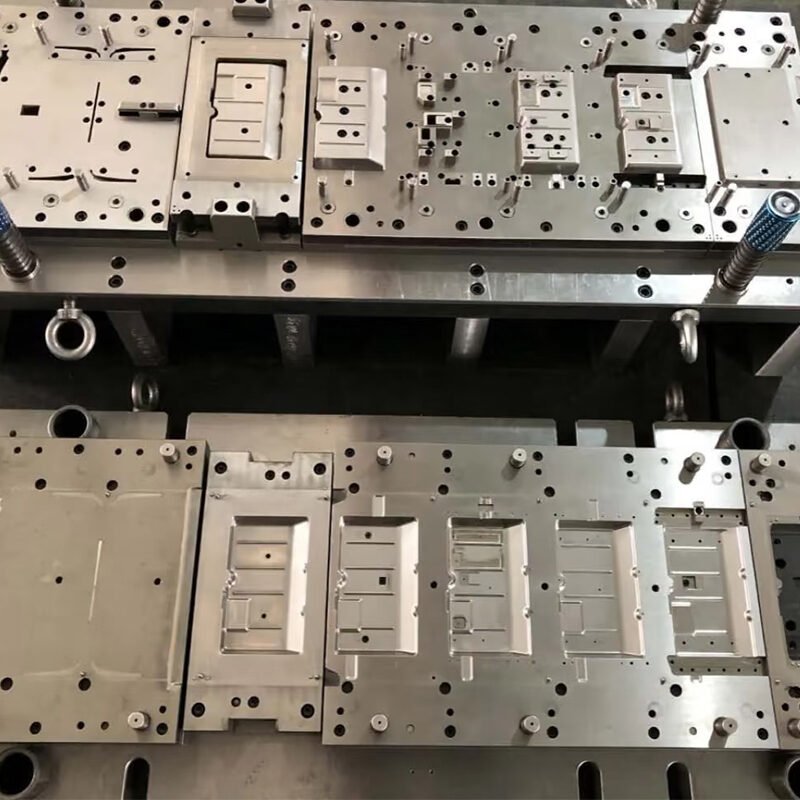

This process is built on a simple principle: leverage force to shape materials. The magic, however, isn’t just in the force; it’s in the tooling—the die itself. The die is a custom-engineered tool, often made of hardened steel, that dictates the final shape, size, and features of the part. It’s the blueprint, the mold, and the cutting tool all in one. The precision of the die is what ensures that the millionth part is identical to the first.

When a job comes in, we’re not just thinking about the stamping process; we’re thinking about the entire lifecycle of the part. We start with raw sheet metal, which comes in large rolls or flat blanks. This is the foundation. The sheet is fed into the press, and with each cycle of the press, a new part is born. A powerful ram in the press moves the punch down to engage with the die, performing a range of operations from cutting to bending.

The beauty of metal stamping is its efficiency and repeatability. It’s a fast, reliable way to produce thousands or even millions of identical parts with extremely tight tolerances. It’s the go-to method for high-volume production where precision and cost-effectiveness are non-negotiable. While the upfront cost for a custom die can be significant, the cost per part drops dramatically as the volume increases, making it one of the most economical manufacturing solutions for mass production. It’s a process that has stood the test of time, evolving from simple hand-operated presses to today’s high-speed, computer-controlled systems. The fundamental principle remains the same, but the technology has made it faster, more precise, and more versatile than ever before.

A Closer Look at Key Stamping Processes and Techniques

When I first started in this industry, I was amazed by the sheer number of operations you could perform with a punch press and a well-designed die. People often think of stamping as a single, uniform process, but it’s really an umbrella term for a variety of techniques, each serving a specific purpose. Let’s break down some of the most common ones we use to create those precise, complex parts.

First, there’s Blanking. This is probably the most basic and crucial operation. Blanking is when you use a punch and die to cut a complete part, or “blank,” from the sheet metal strip. The part we keep is the one that’s cut out, and the surrounding material is the scrap. It’s essentially the inverse of punching.

Speaking of which, Piercing and Punching are about making holes. While blanking creates a complete part, piercing or punching cuts a hole or a specific shape out of a larger piece of metal that will continue on to become the final product. We use this for everything from bolt holes in a bracket to intricate vent patterns in a computer chassis.

Then we have the shaping processes. Bending and Forming are used to create angles and curves in the sheet metal. This is how we get everything from simple L-brackets to complex U-channels. The punch presses down on the metal, forcing it to take the shape of the die. It’s a fundamental part of creating three-dimensional parts from a two-dimensional material.

For truly deep, hollow parts, we turn to Deep Drawing. This is a fascinating and intricate process. Imagine pulling a flat sheet of metal over a die to form a cup or a container, without any seams. That’s deep drawing. It requires a specific press setup and careful control to stretch the metal without tearing or wrinkling it. It’s the process used to make things like sink basins, fire extinguisher shells, and even some beverage cans.

For features that require extremely high precision, like embossed logos or text, we use Coining. This process involves applying very high pressure—often much greater than that used for other stamping operations—to the metal. This pressure causes the metal to flow into the die’s cavities, reproducing fine details with incredible accuracy. The name comes from its use in making coins, which require sharp, clear details.

But the real game-changer, especially for high-volume jobs, is Progressive Die Stamping. This is a marvel of engineering. Instead of performing one operation at a time, a progressive die is a long, multi-station tool. The metal strip is fed through the die step-by-step. In the first station, we might pierce a hole. In the next, we might bend an edge. And in the final station, we perform the blanking operation to cut the finished part from the strip. Each stroke of the press produces a finished part, making it an incredibly fast and efficient process for manufacturing millions of identical components. When you see a machine producing a part every second, it’s almost always progressive die stamping at work.

The Materials, Tooling, and Equipment of Stamping

As someone who’s spent years in this business, I can tell you that the secret to a perfect stamped part isn’t just in the process itself—it’s in the materials we choose, the tools we build, and the machinery we operate. They are the three pillars that support the entire operation.

Let’s start with the materials. When a customer comes to us, one of the first questions we ask is, “What is this part for?” The answer to that question dictates the material we’ll use. We work with a huge variety of sheet metal types, each with its own unique properties. Stainless steel is a workhorse, known for its corrosion resistance and strength—perfect for medical devices or kitchen components. Aluminum is prized for its lightweight nature, making it the go-to for aerospace and automotive applications where weight is a critical factor. Copper and brass are fantastic for electronics, thanks to their exceptional electrical conductivity. For general-purpose parts that require a balance of strength and cost-effectiveness, we often turn to various steel alloys. The choice of material affects everything, from the force required to stamp it to its final properties.

Next up is the tooling—and this is where the magic really happens. The heart of the entire stamping operation is the stamping die. A good die is a masterpiece of engineering. It’s a precision tool, often made from hardened tool steel, that’s designed and built to withstand millions of cycles under immense pressure. Whether it’s a simple die for a single-stage blanking operation or a complex progressive die with multiple stations, its design is what determines the final part’s geometry and tolerances. When a die is well-maintained, it can produce a part so consistently that you could swap out a part from a batch made today with one made five years ago, and they would be identical. Building and maintaining this tooling is a specialized skill, and a high-quality die is an investment that pays for itself many times over through reliable, repeatable production.

Finally, we have the equipment itself—the punch press. These machines are beasts. There are three main types: mechanical, hydraulic, and servo presses. Mechanical presses are the most common for high-speed, high-volume operations like progressive die stamping. They use a flywheel and a crank mechanism to deliver powerful, rapid strokes. Hydraulic presses are slower but offer a lot of control over force and stroke, making them great for deep drawing and forming. Servo presses are the new kids on the block, using advanced motors to provide unparalleled control over the ram’s speed and position throughout the stroke. This flexibility allows us to fine-tune the process for even the most challenging materials and designs. The combination of the right material, a meticulously crafted die, and a powerful, precise press is what allows us to produce everything from a simple washer to a complex automotive bracket with pinpoint accuracy.

Key Advantages and Applications Across Industries

One of the most rewarding parts of my job has always been seeing the incredible variety of things we can create with metal stamping and understanding its impact on the real world. This isn’t just a niche process; it’s a fundamental pillar of modern manufacturing, and it’s all thanks to its core benefits.

The first and most significant advantage is high-speed, high-volume production. Once a die is built and installed, a stamping press can produce hundreds, sometimes thousands, of parts per minute. This incredible speed is why it’s the go-to method for any product that needs to be made in the millions. Think of the internal components of an electronic device or the countless brackets and fasteners in a car—stamping is the only way to meet that demand efficiently.

Coupled with speed is exceptional precision and repeatability. The die acts as a rigid, unyielding template. As I mentioned before, this ensures that the first part we make is dimensionally identical to the last, even if we run the press for a year straight. This is critical for industries that demand tight tolerances, where a part needs to fit perfectly with other components. For example, in the automotive industry, a misaligned bracket could lead to a safety issue, and in electronics, a slightly off-sized connector can render a device useless.

From a business perspective, the biggest win is cost-effectiveness. While the initial investment in a custom die can be high, the cost per part plummets as production volume increases. The speed and minimal labor required for operation make it a lean manufacturing solution. Plus, stamping is very efficient with materials. Operations like blanking and piercing are designed to minimize material waste, and any scrap metal is typically collected and recycled, which adds to the process’s overall sustainability.

Because of these benefits, you’ll find metal stamped parts everywhere you look. In the automotive industry, they are used for everything from structural body components and brackets to engine and exhaust parts. The electronics sector relies on stamping for intricate connectors, contacts, terminals, and casings for everything from smartphones to computers. The medical devices industry uses it for precision parts in surgical tools, implants, and diagnostic equipment, where accuracy is a matter of life and death. The aerospace industry uses stamping to create lightweight, strong components for aircraft. And in consumer goods, you’ll find stamped parts in appliances, kitchenware, and furniture. It’s truly a process that

The Future of Metal Stamping: Innovation and Related Concepts

The world of manufacturing is always evolving, and metal stamping is no exception. While the core principles have remained constant for over a century, the technology and the demands placed on it have pushed the industry to new heights.

One of the most significant shifts I’ve seen is the move towards precision metal stamping. This isn’t just about making parts—it’s about making parts with incredibly tight tolerances. Think of a part that has to be flawless down to a thousandth of an inch. Achieving this requires not only superior dies but also advanced sensor technology and sophisticated computer-controlled presses that can monitor and adjust pressure in real-time. This level of precision is non-negotiable for industries like medical and aerospace, where a small error can have catastrophic consequences. It’s a testament to how far we’ve come from the simple punch presses of the past.

Beyond stamping itself, it’s crucial to understand how it fits into a larger manufacturing ecosystem. We rarely stamp a part and consider the job done. Often, the finished part needs to be integrated with other components. This is where stamping intersects with other processes like CNC machining, welding, and various finishing techniques like plating, powder coating, or anodizing. The efficiency of the stamping process allows us to produce the core component quickly and cost-effectively, so we can then focus on these secondary operations. It’s not about stamping versus other methods; it’s about how stamping can be the high-speed backbone of a complex assembly.

For businesses and customers, the cost factors are always a key consideration. While the cost per piece is incredibly low in high-volume runs, the initial investment in a custom die is the largest cost. We work closely with clients to explain this dynamic—that while the upfront cost of the stamping die design might seem steep, it’s a long-term investment that unlocks significant savings. The material type also plays a huge role in the final price, with materials like stainless steel and copper being more expensive than standard steel alloys.

As we look ahead, I’m excited about the future. I see a greater emphasis on automation and robotics to handle parts and dies, further increasing safety and efficiency. The use of real-time data and artificial intelligence will help us predict maintenance needs and optimize production runs. And, most importantly, there’s a growing commitment to sustainability. By optimizing material use and ensuring that almost all scrap is recycled, metal stamping remains an environmentally conscious choice in manufacturing.

In the end, metal parts stamping is more than just a process; it’s a foundation. It’s the reason so many of the products we rely on are so precise, reliable, and accessible. It’s a craft that combines engineering, metallurgy, and design to turn raw metal into the building blocks of our modern world. And after all these years, I’m still proud to be a part of it.